TENSION TESTING

Electroplating is a technique used to protect metals from oxidation and corrosion. This process involves the use of solutions like copper sulphate or magnesium sulphate to apply a protective metal coating on objects. The video task provides insights into how electroplating works, detailing steps such as current flow, electrode interactions, and factors influencing the quality of the coating. Additionally, the text discusses surface finishing methods like shot blasting and hot-dip galvanizing, highlighting their importance in enhancing durability and appearance.

Uploaded on Feb 18, 2025 | 1 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

TENSION TESTING and

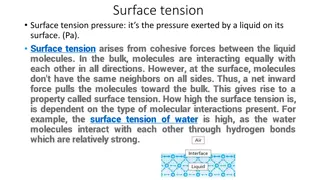

9/1 The video task https://www.youtube.com/watch?v=U9Y8xclePOw First part: 1. Electroplating protects metals from oxidation/ corrosion 2. You need a solution of copper sulphate/ magnesium sulphate to electroplate 3. The process begins when the current/water flows from the power supply 4. There is hydrogen/oxygen on the positive electrode 5. Copper ions in the solution are attracted to both electrodes/negative electrode 6. The copper ions give the solution its green/blue colour

The video task Second part 7. The electrodes hasn t changed their weight. 8. You can electroplate electrodes and objects as well. 9.The quality of the copper cover depends on the volume of current. T / F T / F T / F

Answers corrosion 1. 2. copper sulphate 3. current 4. hydrogen 5. negative 6. blue 7. F 8. T 9. T

9/2 Read and listen to the text http://i3.photobucket.com/albums/y88/TOGWT/HVLPSprayGun_zpsa19bb4be.jpg http://az276019.vo.msecnd.net/valmontstaging/valmont-coatings/big-edge-2-1.jpg?sfvrsn=1 http://www.hiseamarine.com/photos/Horizontal-Movable-Shot-Blasting-Machine.jpg

9/3 Choose the correct term adherence* compressed air* conductive* shot-blasting* curing furnace* electroplating* hot-dip galvanizing* corrosion* powder coating* paint* oxidation* surface finishing* apply* solid* Schopn v stelekt inu, kter je pro pr kov lakov n nezbytn Trval p ilnut k povrchu Vzduch vestla en form u van p i pr kov m lakov n Nan et barvu na povrch v robku nebo sou st Za zen , ve kter m doch z k tvrdnut n t ru Nan en pr ku na povrch sou sti nebov robk pomoc stla en hovzduchu a elektrostatick energie Povrchov prava p ed obr b n m proudem abrazivn ho materi lu, zpravidla ocelov mi broky Chemick rozru en kovov ch materi l p soben mvn j ch vliv O et en povrchov ch ploch v robk nebo sou st Povrchov prava tenkou vrstvou zinku, prov d n pono en m do vysokoteplotn l zn Hmota, zpravidla antikorozn , nan en na povrch v robku nebo sou sti Chemick reakce kovov ch povrch s kysl kem Povrchov pravavyu vaj c elektrickou energii pro p enos kationt Skupenstv , p i n m t l so dr sv j tvar

Answers conductive adherence compressed air apply curing furnace powder coating shot-blasting corrosion surface finishing 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. hot-dip galvanizing 11. paint 12. oxidation 13. electroplating 14. solid

9/4 Choose the correct term. adherence* compressed air* conductive* shot-blasting* curing furnace* electroplating* hot-dip galvanizing* corrosion* powder coating* paint* oxidation* surface finishing* apply* solid* A body solution with a stable shape Able to transmit a current necessary to powder coat A stream of air used to powder coat To coat a surface with a material A device used to heat and harden the paint To spray a powder on a surface with compressed air and electrostatic energy A thin zinc layer Surface treatment coated by passing through a hot bath Permanent sticking to a surface Surface treatment using a stream of abrasive material usually steel particles A surface treatment using power to transfer cations Chemical disintegration of metal materials due to external influence Treatment of product or component surfaces Not anti-corrosive liquid laid on a product or component surface Chemical reaction of metal surfaces and oxygen

Answers solid conductive compressed air apply curing furnace powder coating hot-dip galvanizing adherence shot-blasting 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. electroplating 11. corrosion 12. surface finishing 13. paint 14. oxidation

9/5 Describe the pictures. Popis: http://formaspace.com/images/300x/formaspace_powder_coating_2.jpg

9/6 Work out a dictionary Work out a dictionary for each bold expression in this unit. Put it into alphabetical order Find phonetic transcription Write it into your textbook