The Evolution of SSPC Standards: From Surface Preparation to Sustainability

To specifying surface cleanliness and coating performance, SSPC Standards address environmental and safety concerns. For example, they provide guidance on proper containment of abrasive blasting materials to prevent environmental contamination and en

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

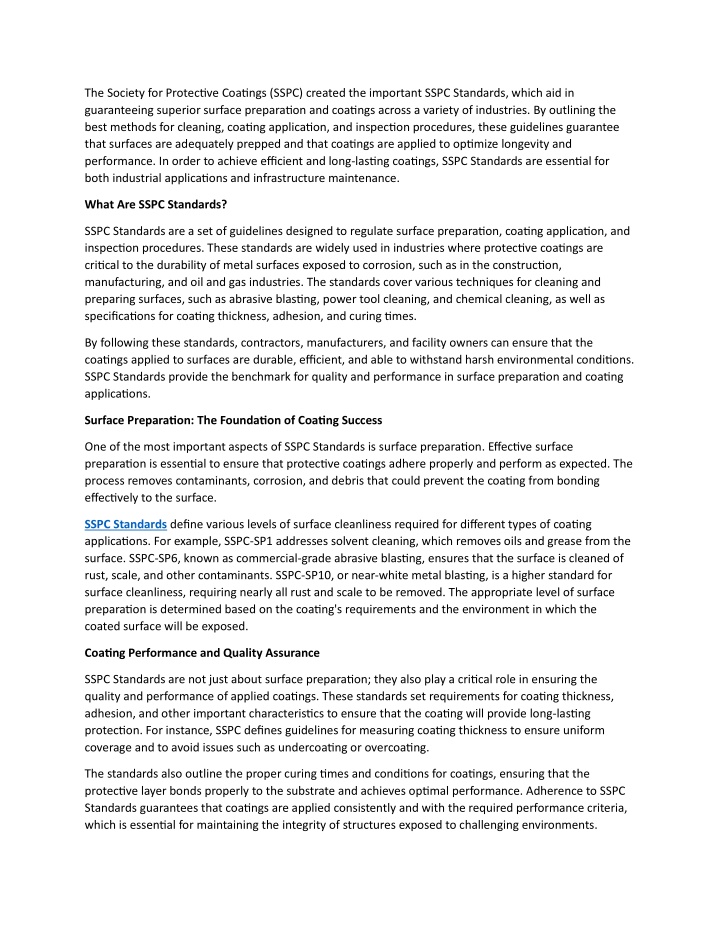

The Society for Protective Coatings (SSPC) created the important SSPC Standards, which aid in guaranteeing superior surface preparation and coatings across a variety of industries. By outlining the best methods for cleaning, coating application, and inspection procedures, these guidelines guarantee that surfaces are adequately prepped and that coatings are applied to optimize longevity and performance. In order to achieve efficient and long-lasting coatings, SSPC Standards are essential for both industrial applications and infrastructure maintenance. What Are SSPC Standards? SSPC Standards are a set of guidelines designed to regulate surface preparation, coating application, and inspection procedures. These standards are widely used in industries where protective coatings are critical to the durability of metal surfaces exposed to corrosion, such as in the construction, manufacturing, and oil and gas industries. The standards cover various techniques for cleaning and preparing surfaces, such as abrasive blasting, power tool cleaning, and chemical cleaning, as well as specifications for coating thickness, adhesion, and curing times. By following these standards, contractors, manufacturers, and facility owners can ensure that the coatings applied to surfaces are durable, efficient, and able to withstand harsh environmental conditions. SSPC Standards provide the benchmark for quality and performance in surface preparation and coating applications. Surface Preparation: The Foundation of Coating Success One of the most important aspects of SSPC Standards is surface preparation. Effective surface preparation is essential to ensure that protective coatings adhere properly and perform as expected. The process removes contaminants, corrosion, and debris that could prevent the coating from bonding effectively to the surface. SSPC Standards define various levels of surface cleanliness required for different types of coating applications. For example, SSPC-SP1 addresses solvent cleaning, which removes oils and grease from the surface. SSPC-SP6, known as commercial-grade abrasive blasting, ensures that the surface is cleaned of rust, scale, and other contaminants. SSPC-SP10, or near-white metal blasting, is a higher standard for surface cleanliness, requiring nearly all rust and scale to be removed. The appropriate level of surface preparation is determined based on the coating's requirements and the environment in which the coated surface will be exposed. Coating Performance and Quality Assurance SSPC Standards are not just about surface preparation; they also play a critical role in ensuring the quality and performance of applied coatings. These standards set requirements for coating thickness, adhesion, and other important characteristics to ensure that the coating will provide long-lasting protection. For instance, SSPC defines guidelines for measuring coating thickness to ensure uniform coverage and to avoid issues such as undercoating or overcoating. The standards also outline the proper curing times and conditions for coatings, ensuring that the protective layer bonds properly to the substrate and achieves optimal performance. Adherence to SSPC Standards guarantees that coatings are applied consistently and with the required performance criteria, which is essential for maintaining the integrity of structures exposed to challenging environments.

Environmental and Safety Standards in Coating Applications SSPC Standards also focus on environmental sustainability and worker safety. Surface preparation and coating applications, particularly those involving abrasive blasting or solvent-based cleaning, can generate significant amounts of dust and chemical emissions. SSPC Standards emphasize proper containment of contaminants and encourage the use of environmentally friendly materials and methods whenever possible. Additionally, the standards outline proper safety protocols for workers involved in coating applications. These guidelines help reduce the risk of exposure to harmful chemicals, abrasive materials, or dangerous fumes, ensuring a safer working environment. Adhering to these safety protocols is not only essential for the well-being of workers but also helps companies comply with regulatory requirements for worker protection. Conclusion For surface preparation and coating applications in a variety of industries to be successful, SSPC Standards are essential. SSPC Standards assist guarantee that protective coatings produce durable results in demanding situations by specifying exact cleaning, coating, and inspection procedures. Additionally, by lowering the chance of coating failure and limiting expensive repairs or maintenance, the guidelines encourage uniformity, quality, and safety in coating applications. SSPC Standards provide the thorough information required to attain optimal performance for sectors looking for dependable, long-lasting protective coatings.