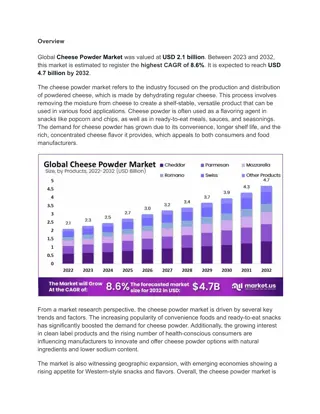

The Ultimate Guide to Mozzarella Cheese Production Techniques

Discover the intricate process of producing Mozzarella cheese, from milk filtration to packaging. Learn about the different types of Mozzarella and key ingredients. Explore traditional methods and the direct acid method. Get insights into cutting, cooking, stretching, and brining. Dive into the world of this Italian classic known for its stretchy and melting qualities.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

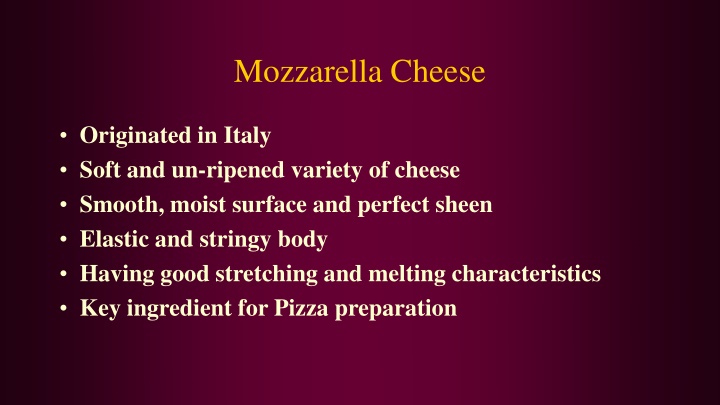

Mozzarella Cheese Originated in Italy Soft and un-ripened variety of cheese Smooth, moist surface and perfect sheen Elastic and stringy body Having good stretching and melting characteristics Key ingredient for Pizza preparation

Type of Mozzarella Type Mozzarella Low Moisture Mozzarella Part-skim Mozzarella Low- Moisture Part-skim Mozzarella Moisture (%) FDM (%) 52-60 < 45 45-52 < 45 52-60 >30<45 45-52 >30<45

Mozzarella Cheese Milk Filtration/Clarification Standardisation (3- 4% fat) Pasteurization (63 C/30 min.) Cooling (31 C) Starter addition [Streptococcus thermophilus and Lactobacillus bulgaricus (1:1) @ 1-2%] Rennet addition (1.5 g/100 L milk)

Cutting Cooking (42-44 C) Draining Cheddaring (0.70% acidity) Milling Plasticising /stretching under hot water (80-85 C) Moulding Brining (20-22% chilled brine) Packaging

Direct Acid Method Skim milk Filtration/Clarification Standardization Pasteurization (63 c/30/min.) Chilling (4-8 c) Acidifying Heating Rennet addition

Cutting Cooking Draining Plasticizing/stretching under hot water (80-85 C) Moulding Brining (20-22%) chilled brine) Packaging Storage