Thermocouples for Temperature Measurement

Explore the use of thermocouples as temperature measuring devices in hard-to-reach areas, their components, errors, and correction factors. Learn about experimentation methods, simulation techniques, and tools like Abaqus and JMP for analysis. Discover the value of formal Design of Experiments (DOE) approaches to minimize errors and optimize measurements.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

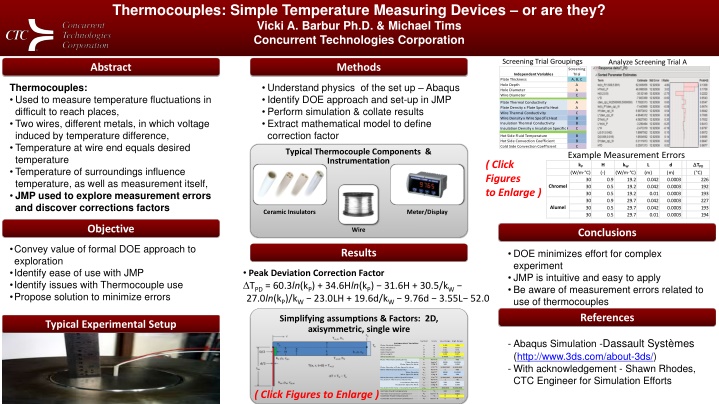

Thermocouples: Simple Temperature Measuring Devices or are they? Vicki A. Barbur Ph.D. & Michael Tims Concurrent Technologies Corporation Screening Trial Groupings Analyze Screening Trial A Abstract Methods Screening Trial A, B, C A A C Independent Variables Plate Thickness Hole Depth Hole Diameter Wire Diameter Understand physics of the set up Abaqus Identify DOE approach and set-up in JMP Perform simulation & collate results Extract mathematical model to define correction factor Thermocouples: Used to measure temperature fluctuations in difficult to reach places, Two wires, different metals, in which voltage induced by temperature difference, Temperature at wire end equals desired temperature Temperature of surroundings influence temperature, as well as measurement itself, JMP used to explore measurement errors and discover corrections factors Plate Thermal Conductivity Plate Density x Plate Specific Heat Wire Thermal Conductivity Wire Density x Wire Specific Heat Insulation Thermal Conductivity Insulation Density x Insulation Specific Heat C A A C B B Hot Side Fluid Temperature Hot Side Convection Coefficient Cold Side Convection Coefficient B B C Typical Thermocouple Components & Instrumentation Example Measurement Errors kP H kW (W/m C) (-) (W/m C) 30 0.9 30 0.5 30 0.5 30 0.9 30 0.5 30 0.5 ( Click Figures to Enlarge ) TPD ( C) L d (m) 0.042 0.042 0.01 0.042 0.042 0.01 (m) 0.0003 0.0003 0.0003 0.0003 0.0003 0.0003 19.2 19.2 19.2 29.7 29.7 29.7 226 192 193 227 193 194 Chromel Alumel Ceramic Insulators Meter/Display Objective Wire Conclusions Convey value of formal DOE approach to exploration Identify ease of use with JMP Identify issues with Thermocouple use Propose solution to minimize errors DOE minimizes effort for complex experiment JMP is intuitive and easy to apply Be aware of measurement errors related to use of thermocouples Results Peak Deviation Correction Factor TPD = 60.3ln(kP) + 34.6Hln(kP) 31.6H + 30.5/kW 27.0ln(kP)/kW 23.0LH + 19.6d/kW 9.76d 3.55L 52.0 References Simplifying assumptions & Factors: 2D, axisymmetric, single wire Typical Experimental Setup - Abaqus Simulation -Dassault Syst mes (http://www.3ds.com/about-3ds/) - With acknowledgement - Shawn Rhodes, CTC Engineer for Simulation Efforts Symbol Units Low Range High Range Independent Variables Plate Outside Radius Plate Thickness Hole Depth Hole Diameter Wire Length Wire Diameter ro L H D Lw d m m m m m m 1.00 0.01 0.2L 0.006 0.25 0.0003 1.00 0.10 0.9L 0.016 0.25 0.0050 Plate Thermal Conductivity k r cp rcp kw rw cp,w rcp kI rI cp,I W/m K kg/m3 J/kg K 5 400 20,000 1000 Plate Density Plate Specific Heat 2000 100 J/m3 K W/m K kg/m3 J/kg K J/m3 K W/m K kg/m3 J/kg K J/m3 K Plate Density x Plate Specific Heat Wire Thermal Conductivity 2,000,000 5 4,500,000 400 Wire Density Wire Specific Heat 5000 100 22,000 700 Wire Density x Wire Specific Heat Insulation Thermal Conductivity 2,500,000 1 5,000,000 40 Insulation Density Insulation Specific Heat 750 750 7000 1500 Insulation Density x Insulation Specific Heat rcp 100,000 3,040,000 ( Click Figures to Enlarge ) T ,1 h1 T ,2 h2 Hot Side Fluid Temperature C 100 2000 W/m2 K C W/m2 K Hot Side Convection Coefficient Cold Side Fluid Temperature 5 0 5000 0 Cold Side Convection Coefficient 5 100

The Heat Transfer Model Simplifying assumptions: 2D, axisymmetric, single wire Click Here to Return

Range of Factors Symbol Units Low Range High Range Analysis for metal plates Independent Variables Plate Outside Radius Plate Thickness Hole Depth Hole Diameter Wire Length Wire Diameter ro L H D Lw d m m m m m m 1.00 0.01 0.2L 0.006 0.25 0.0003 1.00 0.10 0.9L 0.016 0.25 0.0050 Plate Thermal Conductivity k r cp rcp kw rw cp,w rcp kI rI cp,I W/m K kg/m3 J/kg K 5 400 Plate Density Plate Specific Heat 2000 100 20,000 1000 J/m3 K W/m K kg/m3 J/kg K J/m3 K W/m K kg/m3 J/kg K Plate Density x Plate Specific Heat Wire Thermal Conductivity 2,000,000 5 4,500,000 400 Wire Density Wire Specific Heat 5000 100 22,000 700 Wire Density x Wire Specific Heat Insulation Thermal Conductivity 2,500,000 1 5,000,000 40 Insulation Density Insulation Specific Heat 750 750 7000 1500 J/m3 K Insulation Density x Insulation Specific Heat rcp 100,000 3,040,000 T ,1 h1 T ,2 h2 Hot Side Fluid Temperature C 100 2000 W/m2 K C W/m2 K Hot Side Convection Coefficient Cold Side Fluid Temperature 5 0 5000 0 Click Here to Return Cold Side Convection Coefficient 5 100

Screening Trial Groupings Screening Trial A, B, C A A C Independent Variables Plate Thickness Hole Depth Hole Diameter Wire Diameter Plate Thermal Conductivity Plate Density x Plate Specific Heat Wire Thermal Conductivity Wire Density x Wire Specific Heat Insulation Thermal Conductivity Insulation Density x Insulation Specific Heat C A A C B B Hot Side Fluid Temperature Hot Side Convection Coefficient Cold Side Convection Coefficient B B C Click Here to Return

Analyze Screening Trial A Click Here to Return

Example Measurement Errors TPD ( C) kP H (-) kW L d (W/m C) (W/m C) (m) 0.042 0.042 0.01 0.042 0.042 0.01 (m) 0.0003 0.0003 0.0003 0.0003 0.0003 0.0003 30 30 30 30 30 30 0.9 0.5 0.5 0.9 0.5 0.5 19.2 19.2 19.2 29.7 29.7 29.7 226 192 193 227 193 194 Chromel Alumel Click Here to Return