Torrefaction and Pyrolysis of Lignocellulosic Biomass for Renewable Fuel Production

This research project focuses on the torrefaction and pyrolysis processes to convert lignocellulosic biomass, such as switchgrass and corn stover, into fungible fuels. The aim is to isolate lignin from biomass using Deep Eutectic Solvents (DES) Fractionation and then convert this lignin into drop-in fuels through pyrolysis. The project involves characterizing DES, screening the best solvents, and examining the torrefaction process to separate hemicellulose and cellulose from the lignin. The ultimate goal is to assess the technical and economic feasibility of producing renewable fuels from lignocellulosic biomass.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Torrefaction and Pyrolysis of Lignocellulosic Biomass to Fungible Fuels PI: Douglas Raynie1 Co-PIs: Lin Wei2, James Julson2 1. Department of Chemistry 2. Department of Agricultural & Biosystems Engineering South Dakota State University March 2015

Background Funded by DOT through NC Sun Grant Initiative in July 2012. The goal is to develop an effective process for isolating lignin from lignocellusloic biomass and thus pyrolyze the lignin to drop in fuels. Specific objectives Isolate/separate lignin from switchgrass, prairie cordgrass, and corn stover using Deep Eutectics Solvents (DES) Fractionation and torrefaction Convert the lignin to drop-in fuels using pyrolysis Preliminary evaluation of tech-economic feasibility of the process

Lignocellulosic Biomass Components cellulose, hemicelluloses, and lignin make up dry matter of biomass > 90% Small amounts of extraneous organic compounds (1- 4%) and about 6% others http://pubs.acs.org/cen/coverstory/86/8633cover3.html

Deep Eutectics Solvents (DES) Fractionation Prepare DES: Sixteen DES that combine quaternary ammonium salts (QAS) choline chloride and acetylcholine chloride and hydrogen bond donors (HBD) urea and glycerol with different ratios. Characterization of DES Determination of crystallization temperature, density, pH, Octanol-water partition coefficients, viscosity, etc. Screening the best DES Solubility determination of the DES using 1: 4 of solute to DES ratio

Lignin separation using torrefaction Torrefaction is a mild pyrolysis at temperatures typically between 200 and 350 C. No air 200 350oC Biomass Heat Sizing and drying 200 350 C.

Lignin Separation Procedure Hemicellulose is decomposed by controlled torrefaction Cellulose is washed out using DES Lignin is separated from cellulose solution Key factors of torrefaction Feedstock species: corn stover, switchgrass, prairie grass, etc. Reaction conditions: heating rate, temperature, retention time, etc. Bio-char Potential Solid fuel for electricity/heating Co-firing with coal for electricity/heating Convert to liquid fuels through pyrolysis or gasification

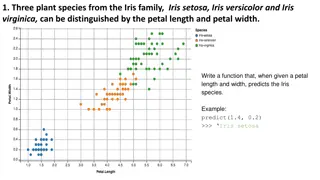

Feedstock Preparation Corn stover, switchgrass, and prairie grass were ground into powders Blending of the three feedstocks at a weight ratio of 1:1:1 (a) (b) Prairie Grass Max./mm1.51 Min./mm 0.01 Mean/mm 0.25 Cornstover Max./mm 7.84 Min./mm 0.04 Mean/mm 0.66 15 10 Percentage (%) Percentage (%) 10 5 5 0 0 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Particle size (mm) Particle size (mm) Blending (d) Switch grass Max./mm 1.00 Min./mm 0.02 Mean/mm 0.15 35 (c) 30 25 Percentage (%) 20 15 10 5 0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 Particle size (mm) Particle size analyses of corn stover (a), switchgrass (b), prairie grass (c), and the blending of corn stover, switchgrass, and prairie grass at a weight ratio of 1:1:1(d)

Torrefaction System Control: temperatures, pressure, and oxygen presenting Flow meter Condenser Thermocouple Nitrogen Coolant GC Exhaust gas Reactor Biomass Coolant Tee-valve Heating furnace Collector Gas washing Flowchart of the batch torrefaction reactor

Torrefaction Products The yield rates of bio-char, bio-oil, and off-gases 250 C 300 C 350 C Bio-char 80 60 % 40 20 0 Blend CS SG PG Feedstock types Bio-oil 60 250 C 300 C 350 C 40 % 20 0 Blend CS SG PG Feedstock types Off-gas 40 250 C 300 C 350 C % 20 0 Blend CS SG PG Feedstock types Note: CS: corn stover; SG: switchgrass; PG: prairie grass; Blend: CS, SG, and PG blending in a weight ratio of 1:1:1

Characterization of Feedstocks and Bio-chars Proximate and ultimate analysis of the raw feedstocks Feedstock Blend 7.17 17.17 Elemental analysis, wt.% ( dry basis) - - - CS 0.17 0.25 SG 0.11 0.19 PG 0.14 0.23 MC, wt.% (wet basis) Higher heating value (HHV), MJ/Kg 0.22 0.31 7.75 17.46 6.50 17.64 7.25 16.58 C H N 42.36 5.97 4.23 0.47 0.02 0.11 43.94 5.91 4.51 0.11 0.04 0.08 44.27 5.82 4.13 0.62 0.04 0.07 R (oxygen and traces of other elements) - 47.43 0.60 45.63 0.06 45.77 0.73 Elemental analysis results of bio-chars produced in torrefaction at different temperatures 250 C 300 C 350 C Feedstocks C H N R C H N R C H N R CS 51.84 5.31 4.84 38.01 58.75 4.30 5.29 31.65 60.31 3.82 4.75 31.11 SG 55.01 5.62 4.95 34.42 67.79 4.55 5.78 21.87 70.95 4.08 5.04 19.91 PG 57.28 5.47 4.76 32.48 65.14 4.66 5.01 25.19 66.28 4.13 5.32 24.26 Blend 53.21 5.30 1.89 39.62 62.4 4.67 2.10 30.84 64.47 3.94 2.42 29.17

Determination of lignin content after torrefaction Determinations of hemicelluloses, cellulose and lignin contents in the raw feedstocks and their torrefied residues (bio-char) produced at three different temperatures (200, 250, 300 oC). Methods: clean fraction and hydrolysis methods individually. Solvent used in clean fraction: MIBK (45%) + Ethanol (35%) + Water (20%) + H2SO4(0.5%) A standard hydrolysis method written by NREL was used to determine structural carbohydrates and lignin as contrast.

Lignin Content Lignin content (%) determined by clean fraction 30 CS SG PG 25 20 lignin, % 15 10 5 0 200 C 250 C 300 C 350 C torrefaction temperature

Biomass Carbonization Content (%) of (solid carbon + acid insolvable lignin) determined by Hydrolysis method (NREL) Acid insolvable lignin and solid carbon 100 90 80 70 60 50 % 40 30 CS SG PG 20 10 0 Raw 200 C 250 C 300 C 350 C Temperature

Next phase of the project Separate lignin from the bio-chars produced Identify the optimal conditions of torrefaction to improve bio-char yield and quality for lignin separation Convert lignin into bio-oil using catalytic fast pyrolysis (CFP) Upgrade the bio-oils to drop-in fuels

Summary Corn stover, switchgrass, and prairie grass and their blend can be torrified into three products: bio-char, bio-oil, and off-gases. Lignin contents significantly decrease when temperatures increase. Torrefactoin temperatures have significant effects on yield rates and properties of the bio-chars. Feedstock species have less influences on yield rates and properties of the bio-chars if torrefaction at the same temperature. There is no significant interaction between temperatures and feedstock species on yield rates and properties of the bio-chars.

Acknowledgment Research teams: Postdoc: Yang Gao, Chunkai Shi Graduate students: Wangda Qu, Yinbin Huang, Shouyun Cheng, Zhongwei Liu, Xianhui Zhao GCMS analyses helped by Ms. Shanmugapriya Dharmarajan, Mr. John Kiratu, and Ms. Changling Qiu in the Chemistry Dept. SDSU Funding supported by DOT : Award #: DTOS59-07-G-00054

Thank you for your attention ! Questions ?

![[PDF⚡READ❤ONLINE] Planet Mercury: From Pale Pink Dot to Dynamic World (Springer](/thumb/21549/pdf-read-online-planet-mercury-from-pale-pink-dot-to-dynamic-world-springer.jpg)