Troubleshooting Bell Belfry Rope Management and Maintenance

Learn about common problems with bell belfry rope management, including tips on maintenance, repairs, and safety precautions. Discover how to address issues like rope slips, wheel alignment, and difficult rope handling for smoother belfry operations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

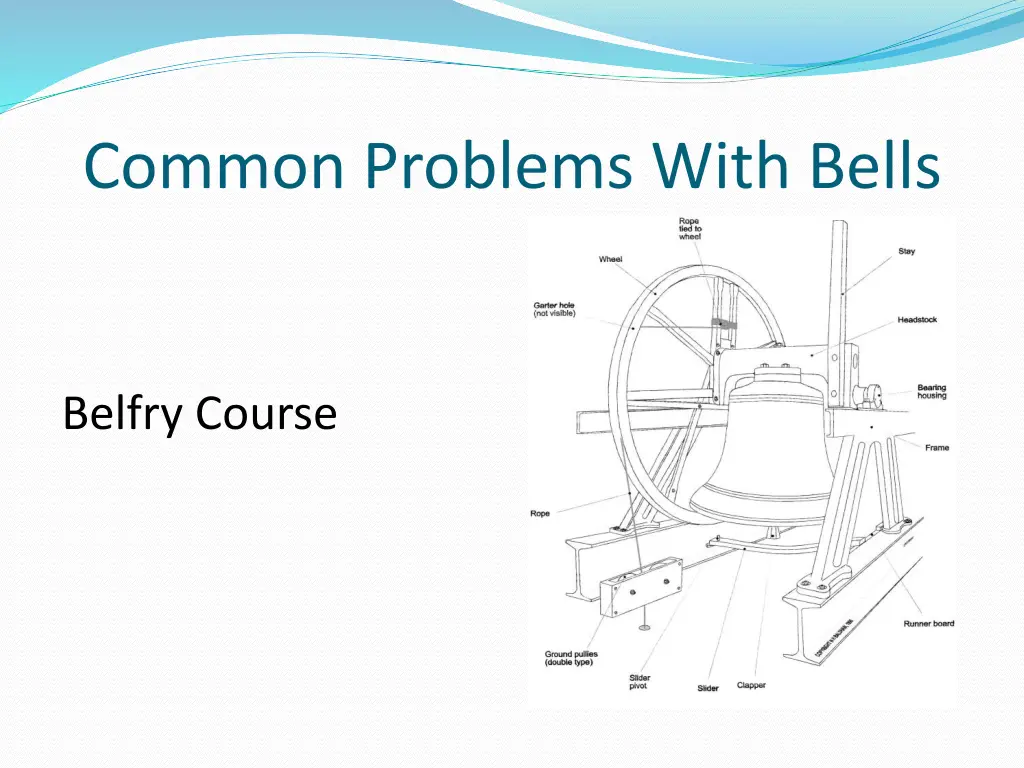

Common Problems With Bells Belfry Course

Rope Management - check the ropes every month - replace only tail if rest is OK. Replace only top if sally & tail OK - extend rope life with polyester tops (reduces stretch and wet weather effect - sally wear from low ceilings or guides - special ceiling bosses and tapered sallies - reposition rope guides (design, faculty) - replace or repair poor pulleys, flapping boards, bosses, rope guides, wheels, garter holes etc - rope tail-end drier (stiff ropes wear faster at any weak point) - appropriate size boxes to save repeated tail-end adjustment - mats or carpet where ropes land on floor - tuck in tail ends properly - protect garter holes with bobbins - garter hole sleeves protect hemp ropes - change rope position on wheel periodically - no sticky tape etc on tail-ends (tuck the tail-end properly) - washing ropes was discussed in the Ringing World (5th October 2018, p 952)

Doing Work in the Belfry Get the permission of the PCC Check the Diocese Faculty Guidelines You may need a Faculty (church planning permission ) depending on the type of work. The diocese website will give guidance or ask your Guild or Association Towers & Belfries committee the DAC Bells Advisor The CCCBR SMWG Depending on the work, you may need to ask Historic England, SPAB etc Minor rope works are probably Faculty exempt, but better to familiarise yourself, just in case!

Rope Slips Wheel Wheel is not running true: Check that the pulley is directly under the wheel. Picture

Rope Slips Wheel Wheel is not running true: With the bell silenced, watch the wheel from a safe place while someone rings the bell. Is it always in line? Video

Rope Slips Wheel Wheel is not running true: Obstruction in wheel groove. Check all the way round. Picture

Difficult or Unruly Rope Rope drop is poor

Maintenance schedule Monthly check tails & sallies Quarterly check ropes above sallies (monthly if not polyester tops) Half yearly check rope runs for any new splinters, roughness or snagging

Different Types of Ropes Boat ropes Etc Polyester Hemp

Types of Splice Short splice (splice not going over pulleys) Back splice Eye splice Long splice (splice over pulleys)

Artefacts Wheel Bosses Ropes Polyester Model bell Pulleys