Understanding Material Deformation Properties

Explore Poisson's ratio, plastic deformation, tensile properties, and material behavior under stress in this informative guide. Learn about yielding, ductility, toughness, and more essential concepts in material science.

Uploaded on | 1 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

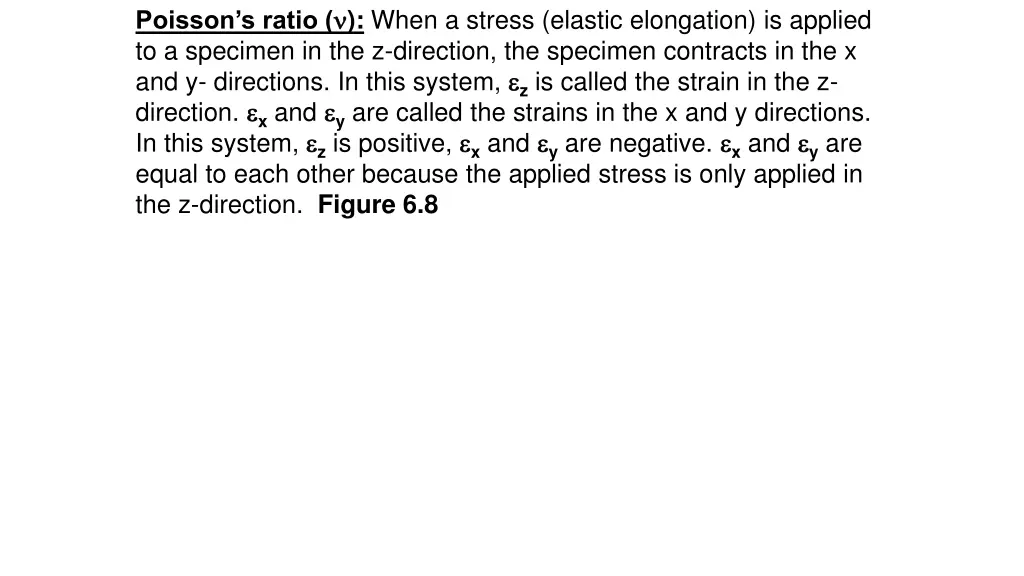

Poissons ratio ( ): When a stress (elastic elongation) is applied to a specimen in the z-direction, the specimen contracts in the x and y- directions. In this system, zis called the strain in the z- direction. xand yare called the strains in the x and y directions. In this system, zis positive, xand yare negative. xand yare equal to each other because the applied stress is only applied in the z-direction. Figure 6.8

Figure 6.4: Stress-strain plot for an elastic deformation

Poissons ratio( ) is the ratio of lateral stains ( xand y) to the axial strain ( z). x y = = z z Plastic Deformation: For most materials, after strains of 0.005, elastic deformation is no longer true. After strains of 0.005, the stress is no longer directly proportional to the strain. After strains of 0.005, plastic deformation occurs. Figure 6.9.a

TENSILE PROPERTIES: These are the properties related to the deformation behavior of a material. Yielding (akma): If a material is deforming plastically, this is called yielding. Proportional Limit: The initial point where the stress-strain curve deviates from linearity is called the proportional limit. The point P in Figure 6.9.a Yield Strength: The yield strength is defined as the stress at which a material begins to deform plastically. Its symbol is y.

Tensile Strength: It is the maximum stress on the stress-strain curve. Figure 6.10 A small necking forms in the material after the tensile strength point on the stress-strain curve. Necking (Boyun verme): The contraction (daralma) of the specimen at its middle point. At point F in Figure 6.10, the specimen fractures or ruptures due to its break from the necking region. Fracture Strength: It is the fracture or rupture stress at the fracture point (F) on the stress-strain curve of Figure 6.10.

Ductility: It is the degree of plastic deformation upto the fracture point of a material. Ductile: If a material experiences a plastic deformation upto the fracture point, then it is called a ductile material. Brittle: If a material experiences very little or no plastic deformation upto the fracture point, then it is called a brittle material. Figure 6.13 Toughness: It is the ability of a material to absorb energy upto the fracture point. Toughness is the area under the stress-strain curve of a material. Figure 6.13 The unit of toughness is Energy per unit volume. (J/m3)