Understanding Stage 1 Vapor Recovery in Fuel Storage Tanks

Learn about Stage 1 Vapor Recovery systems used to capture hydrocarbon vapors emitted during fuel tank refueling, impacts of proposed tank size changes, EPA comments, and more in this informative article.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

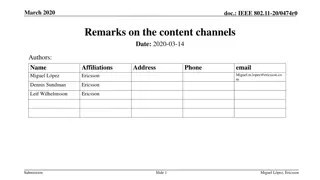

5.220 and 2.260: Stage 1 Vapor Recovery

Purpose of this rulemaking Change the tank size requirement for installing stage 1 vapor recovery from 250-1,000 gallons (2.260) and 500-1,000 gallons (5.220) to a unified 550-1,000 gallons It was found that most tanks between 550 and 1,000 come preinstalled with stage 1 vapor recovery systems. Tanks smaller than 550 gallons do not, requiring retrofits to be compliant with the current rule. Additional changes to clarify language on testing and reporting, along with adding/updating definitions and references Overall decrease the burden on the regulated community

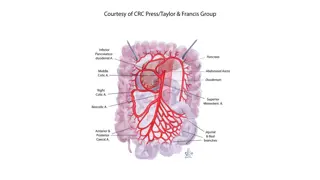

What is Stage 1 Vapor Recovery? System used to retain hydrocarbon vapors emitted from gasoline tanks during refueling Such system are standard on 550 gallon tanks and larger, however smaller tanks would usually require retrofitting

What is the expected impacts? A query was run in our emissions inventory database for all storage tanks, finding 264 and 933 tanks for the Kansas City and St. Louis area respectively, for a total of 1,197 tanks Of these tanks, only two tanks in KC and one tank in StL were identified as being within this threshold change (all three tanks are 500 gallons) One complete cycle of these tanks w/o stage 1 recovery would release 0.002-0.003 tons VOC Such tanks are not expected to receive heavy usage due to their size

EPAs Comments The EPA submitted several comments regarding the proposed rulemakings Several comments had to do with added references to rulemakings that had not yet been approved, however these rules have since been approved and added to 10 CSR 10 One comment addressed the concern of emission increase Other comments are as follows

EPA comments Comment: The rule text at part (3)(C)l .C.(III), proposes to add the ability for an equivalent pressure/vacuum valve to be used as approved by the staff director. The MoDNR should add information to the rule explaining how the staff director will determine equivalency of the pressure/vacuum valve. For example, language could be added indicating that the staff director will determine that a pressure/vacuum valve is equivalent if it has met the alternative test method requirements in 63.7(t) as specified in 40 CFR Part 63. l l 120(a)(l)(ii). Response: Theability for an equivalent pressure/vacuum valve to be used as approved by the staff director was added in part (3)(C) 1.C.(111). The language allows for the staff director to approve a pressure/vacuum valve that is equivalent to that certified by the California Air Resources Board. This addition provides the staff director additional options for determining compliance for pressure/vacuum valves and is adequate for the smaller size tanks covered under this paragraph. The ability of the staff director to determine equivalency is found in multiple areas of the rule. Adding this language on these smaller size tanks to part (3)(C)l .C.(III) will not result in increased emissions or have negative effects on air quality.

EPA Comments Comment: There are two instances in the proposed rule where the MoDNR has decreased the frequency of a testing requirement. In subparagraph (3)(C)2.B the frequency to test Stage I vapor recovery systems for static pressure was increased from every five years to six years. In subparagraph (3)(C)2.C. the frequency to bench test the pressure/vacuum valves pressure was increased from every two years to three years. Because of these changes, the MoDNR will need to submit a demonstration ensuring that the MoDNR's State Implementation Plan submission meets the requirements of Section 110(1) and 193 of the CAA.

EPA Comments Response: The frequency of static pressure and pressure/vacuum valve testing in subparagraphs (3)(C)2.B. and (3)(C)2.C. was changed to allow facilities to perform their testing on the same schedule or cycle. Testing on a two (2) and five (5) year schedule does not allow for coordinated testing and is an unnecessary burden to facilities. Changing to three (3) and six ( 6) year schedules allows for testing to fall on common years. The testing frequency change is also more consistent with the testing frequency found in federal regulations for gasoline dispensing facilities such as 40 CFR 63 Subpart CCCCCC. Changing the testing frequency by one ( 1) year is not expected to result in increased emissions or have negative effects on air quality.

EPA Comments Comment: The rule text proposes to change the general provisions for gasoline loading to apply to "distribution facilities" instead of "loading installations." The MoDNR did not provide a definition for "distribution facility" and the term "loading installation" is only provided in the definition of the term "Stage I vapor recovery system"; without the definitions of "distribution facility" and "loading installation" it is unclear if there is a change in applicability. Also, the MoDNR did not provide information on how many facilities are affected by this change. If there is a real change in applicability, the MoDNR will need to submit a demonstration ensuring that the MoDNR's State Implementation Plan submission meets the requirements of Section 110(1) and 193 of the Clean Air Act, also known as the "anti-backsliding" provisions. These sections relate to the EPA's authority to approve a SIP revision that removes or modifies control measure(s) in the SIP only after the state has demonstrated that such a removal or modification will not interfere with attainment of the National Ambient Air Quality Standards, Rate of Progress, Reasonable Further Progress or any other applicable requirement of the CAA.

EPA Comments Response: The general provisions for gasoline loading to apply to "distribution facilities" instead of "loading installations" was changed to more accurately describe the operation. The change in terms is not intended to change the applicability of the rule or the number of affected sources. The change in terms is also not expected to result in increased emissions or have negative effects on air quality.