Universal Testing Machine for Material Strength Testing

"Learn about the versatile Universal Testing Machine used for standard tensile, compressive, and shear tests on various materials, components, and structures. Explore different tests it can perform and its components, working principle, and applications in determining material properties like hardness and strength."

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

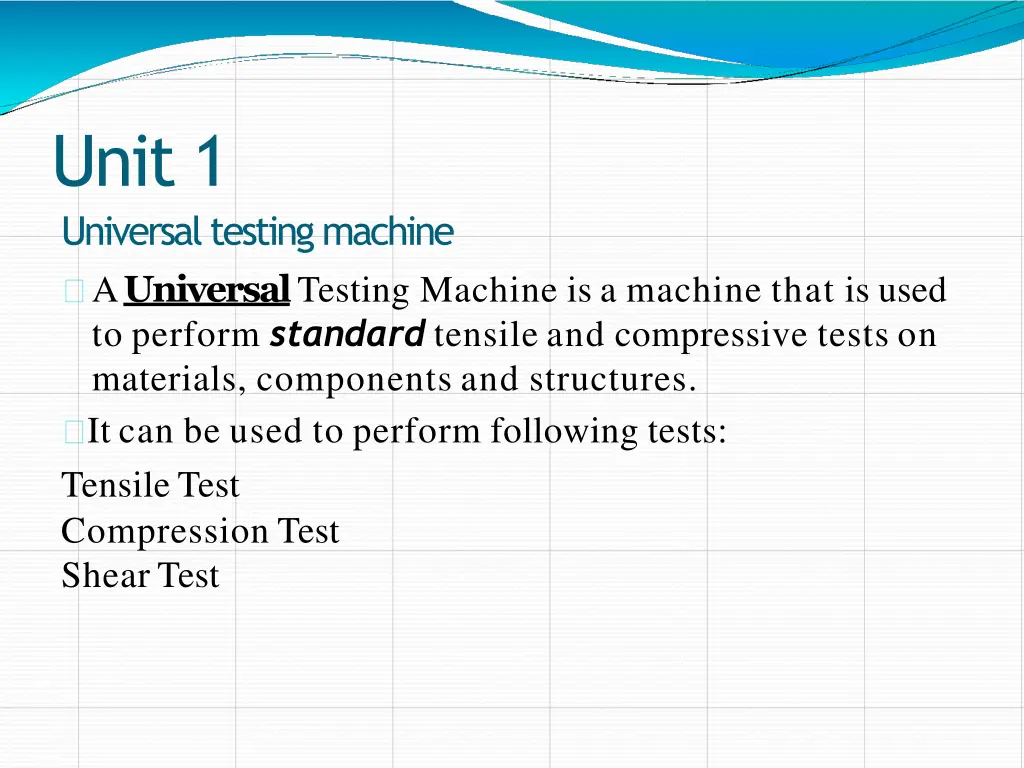

Unit 1 Universal testing machine AUniversalTesting Machine is a machine that is used to perform standard tensile and compressive tests on materials, components and structures. It can be used to perform following tests: TensileTest Compression Test Shear Test

COURSE OUTCOMES After the end of this course, students will be able to: Study and perform on universal testing machine to determine tensile, compression and shear strength. Performance on impact testing machine for different materials for determining impact strength. Experiment on brinell hardness testing machine to determine the hardness of the material . CO405.1 CO405.2 CO405.3 CO405.4 Experiment on Torsion test Experiment on deflection of beam (Simply supported beam) for determining slope and deflection. CO405.6 Experiment on helical spring to determine the deflection of spring CO405.5

Introduction AUniversalTesting Machine is a machine that is used to perform standard tensile and compressive tests on materials, components and structures. It can be used to perform following tests: TensileTest Compression Test ShearTest

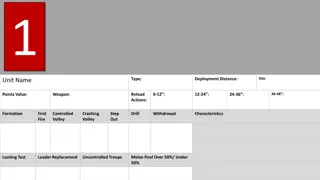

Components..... Loading Unit Load Frame Load Cell Cross Head Control Panel Hydraulic PowerUnit Load Measuring Unit ControlDevices Electric Control Devices Hydraulic ControlDevices Load Indicating Devices

ControlPanel A Control Panel Comprisesof: Power Pack (with drive motor &oil tank) Control Valves Pendulum Dynamometer Load Indicator System Autograph Recorder

WorkingPrinciple It is a load-controlled machine and works on the principleof elongation/deformationofmaterial ontheapplicationofload.

TESTS To assess various rock propertieswe can use different kindof machines among them universal testing machine is one of the most widely used and versatile machine which can measure compressive/tensile/shear strength, directly or indirectly using sample/specimen of rockmass. Compressive strength can be assessed directly but for the tensile and shear strength we need to use different kind of cages and calculations. Tension and Shear tests are conducted by indirect testing. In the Old UTMs, the lower cross head can be raised or lowered rapidly by operating the screwed columns , thus facilitating ease of fixing of test specimen. New UTMs have a fixed table and the adjustable cross head moves up and down.

TENSION CROSSHEAD Notched column SCREW COLUMN DJUSTABLE CROSS HEA A D TABLE LOAD CELL CONTROL PANEL Hydraulic cylinder

OPERTAIONALPROCEDURE Compressivestrength:- Specimen: The cross section of the specimen may be circular, squire, rectangular or in special cases of any other form. Specimens of circular sections are generally be made to thedimensions. Steps 1. Mark the gauge length as per specification and record it accurately. The gauge length should be symmetrical with the length of the bar. 2. Grip the specimen firmly in the jaw of the Universal testing machine and adjust the machine to read zero. 3. Continue loading at increments each time and this loading should be continued till yield point is reached. 4. Record the load at the yield point. That is uniaxial compressive strength of the specimen.

TENSILE STRENGTH:- Specimen: The cross section of the specimen may be circular, squire, rectangular or in special cases of any other form. Speimen of circular sections are generally be made to the dimensions Steps 1. Mark the gauge length as per specification and record it accurately. The gauge length should be symmetrical with the length of the bar. 2. Grip the specimen firmly in the jaw of the Universal testing machine in brazilian cage and adjust the machine to readzero. 3. Continue loading at increments each time and this loading should be continued till yield point is reached.

Shear strength:- Steps 1. Mark the gauge length as per specification and record it accurately. The gauge length should be symmetrical with the length of the bar. 2. Grip the specimen firmly in the jawof the UTM in suitable cage for single shear or double shear and adjust the machine to read zero. 3. Continue loading at increments each time and this loading should be continued till yield point is reached. 4. Record the load at the yield point. That is shear strength of thespecimen.

Single shearcage Double shearcage

PRECAUTIONS 1. Apply the load at a uniform rate and without any jerk. 2. Selection of proper dimension of specimen when testing of different type of strength.