Wastewater Treatment Process for Railway Rolling Stock

This project focuses on developing a decentralized wastewater treatment process for recycling onboard railway rolling stock. The aim is to optimize membrane filtration for water recycling and assess the impact of solid/liquid separation in train wastewater. The study evaluates the characteristics of train wastewater and the challenges posed by low-flush vacuum toilets and prolonged on-board storage on solids separation.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Design and development of wastewater treatment process for recycling on- board the railway rolling stock Neha Jadhava , Prof. Leon Williamsb, Dr Marc Pidoua aCranfield Water Science Institute, Building 52a, Cranfield University, Cranfield, Bedford, MK43 0AL b Centre for Competitive Creative Design , Building 82, Cranfield University, Cranfield, Bedford, MK43 0AL n.jadhav@cranfield.ac.uk, m.pidou@cranfield.ac.uk, l.williams@cranfield.ac.uk Insert profile picture within the frame 9thConference of the UK Wastewater Network 4 November 2021

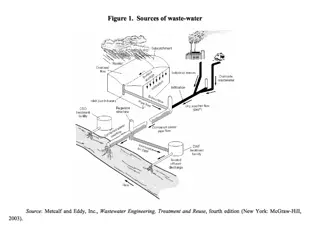

cid:imageebda7a.PNG@5bde6f97.4c80209e Context OLD NEW SUSTAINABLE On-board wastewater treatment Added infrastructure Environmental hazard Complete water recycling Daily emptying Public health hazard Toilets open at all times Toilets still locked out Toilets locked out Aim Objectives Review of decentralised blackwater treatment technology To develop a decentralised wastewater treatment process and further the Train wastewater characteristics & solid/liquid separation understanding of supporting scientific Evaluate and optimise membrane filtration for water recycling knowledge for process optimisation of Impact of storage and processing of faecally contaminated urine on urea hydrolysis water recycling on railway rolling stock

Characteristics of train wastewater Turbidity (NTU) Ammonia (mgL-1) COD (mgL-1) Conductivity (microsiemens cm-1) Total N (mgL-1) pH TSS (gL-1) 10 8000 9 7000 8 6000 7 6 5000 5 4000 4 3000 3 2000 2 1000 1 0 0 High conductivity (upto 6870 S cm-1), and Total N (2340 mgL-1) due to more urination and less dilution of flushwater High variation in turbidity (19 - 1661 NTU) and COD (500 - 7360 mg L-1); supported by proportionally lower faeces levels (upto 5 times) compared to that of gravity flush toilet COD; low TSS range between 0.2 and 2.4 gL-1- greater variability in use of train toilet for defecation resulting into low proportion of solids Greater pH range ~ (between 7 and 8.8) and high ammonia (upto 1048 mg L-1) indicates high occurrence of urea hydrolysis during on-board wastewater storage

Impact of low-flush vacuum toilet and prolonged on-board storage on solids Greatest solid fraction in real train wastewater (33%) is <63 micron in size-significant solids breakage due to on-board storage Real train wastewater (post-vacuum flush and storage) 1.2 8 1.0 Avg. TSS fraction g L-1 7 0.8 6 % VOLUME Size of <63-micron solids actually very small, around 10 microns- escalates solid/liquid separation challenge 0.6 5 4 0.4 3 0.2 2 Comparatively less solid breakage in simulant wastewater without storage; greatest solid fraction >4000 micron- particles can be separated by coarse filtration at front 0.0 1 0 0.01 1 100 10000 Solid particle size (microns) PARTICLE SIZE ( M) Conclusion Simulant wastewater (post-vacuum flush only) Conclusion Technology selection- filtration technology likely to be the most suitable option for solid/liquid separation process 0.9 0.8 0.7 Ratio of TS fraction 0.6 0.5 0.4 0.3 Process implementation for optimal treatment- rapid waste processing from post-flush stage to limit urea hydrolysis and filter relatively larger solids out of the system 0.2 0.1 0.0 Solid particle size (microns)