Wheat Milling Process Overview

Learn about the modern wheat milling process, including steps like cleaning, conditioning, hydro-thermal treatment, and milling into flour and by-products. Discover how wheat is cleaned, conditioned, and milled to produce white flour while maximizing yield. Images provided for visual reference.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

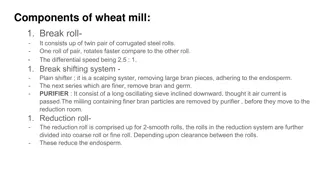

WHEAT MILLING MILLING is a size reduction process. FLOUR MILLING:- - The objective of flour milling is to abstain maximum amount of white flour from wheat endosperm without any bran or germ. The yield of white flour and by-products are 70% and 30% respectively. - The modern milling operations are comprised up of 6 steps: 1. 2. 3. 4. 5. 6. Receiving of wheat, drying and it's storage. Cleaning of wheat. Conditioning of wheat. Milling into flour and by-products. Packing and storage. Blending.

CLEANING:- - Wheat is cleaned to remove all the fine particles and dirt, sticking to the surface of grain. Small pieces of sticks, stones, sands are removed by sieving and light particles like husk are removed by aspiration. Then the wheat is allowed to pass through the magnetic separator to remove fero- magnetic materials. The next step in the cleaning operation is to removal of dirt , sticking to the surface by scoring. The wheat is passed through a stationary emery coated surface. The last step of cleaning is washing in water. - - - - -

Conditioning:- - Conditioning of wheat can be done at room temperature or at elevated temperature. The temperature of wheat should not be raised beyond 47 C. The moisture content of the soft wheat after conditioning should be 17% and that of hard wheat will be 19%. After the moisture of the grain is equilibrated by tempering it for 18-72 hrs. The wheat conditioning is peformed under 3-steps: 1. Pre heating section. 2. Moistening section. 3. Cooling section. - - -

Hydro-thermal conditioning:- Hydro-thermal treatment of grain is done by directly steaming. The grain is heated within 20-30sec. To about 47 C. Milling/Grinding:- - - - - - - - Milling of wheat is carried out by roller mills. The roller milling system is divided into break- roll and reduction-roll system. The break-rolls and reduction-rolls are differentiated will variation in their surface condition. The break roll system, the bran is scraped and kernel is broken up. The endosperm adhering bran is milled away in few steps. Generally, series of 4 break rolls are used. After each break , the mixture of free bran, free endosperm, free germ and endosperm still adhering to bran is passed through next break- roll, while the middle size endosperm are sent to the reduction- roll for formation of flour.