Working with Metals in Industry: Iron, Steel, Titanium, Aluminium & Electroplating

Explore the processes involved in working with metals in industry, from extracting iron to manufacturing titanium, aluminium, and electroplating. Discover how steel is made, properties of different metals, and applications in various industries. Learn about anodising aluminium, electrolysis, and the importance of metals in everyday life.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Metals in Industry, working with metals

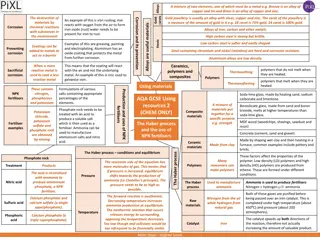

Iron and Steel In previous work we considered the role of the blast furnace in extracting iron from its ore. The iron contains roughly 5% carbon and different metals and is very ________. In order to reduce these impurities and convert the iron into _________ the molten iron is transferred into another furnace where it is mixed with recycled scrap iron and pure ___________. The oxygen reacts with the metal impurities to form ________ oxides. Calcium carbonate is also added to remove some of the acidic oxides as _______ when the furnace is tilted. Words slag, brittle, steel, oxygen, acidic

Making steel the reactions 1) Mixing oxygen with silicon impurities: Silicon + oxygen Silicon oxide 2) Decomposition of limestone: Calcium carbonate calcium oxide + carbon dioxide 3) Adding these products together: Silicon oxide + calcium oxide calcium silicate Eating Out Steel with chromium and nickel is called stainless steel Steel with a high carbon content is strong but brittle Steel with a low carbon content is easily shaped

Titanium Titanium is a strong metal used in planes, replacement hip joints, bikes etc. Two steps are used in its manufacture: Step 1: Convert titanium dioxide (ore) to titanium chloride Step 2: Displace the titanium using sodium or magnesium: Titanium chloride + sodium titanium + sodium chloride In this reaction the titanium is displaced my a more reactive metal. This reaction is done in an argon atmosphere to avoid any further reactions. Titanium ions have a charge of 4+ and gain four electrons to become titanium atoms. This is a reduction reaction.

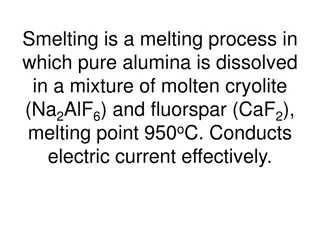

Aluminium Aluminium is a fairly reactive metal that doesn t corrode due to forming a thin layer of aluminium oxide. This explains why greenhouses don t rust and don t need to be painted. A thicker layer of aluminium oxide can be made artificially. There are two stages: 1) Remove the natural layer by placing the aluminium in sodium hydroxide. 2) Use electrolysis on sulphuric acid with the aluminium as the positive electrode. This is called anodising. + + + + - - - - Al H2SO4

Electroplating + + + + - - - - Silver electrode Object to be plated Solution containing silver ions

This powerpoint was kindly donated to www.worldofteaching.com http://www.worldofteaching.com is home to over a thousand powerpoints submitted by teachers. This is a completely free site and requires no registration. Please visit and I hope it will help in your teaching.