Zero Liquid Discharge for Industries: Reducing Environmental Impact and Boosting

Explore how zero liquid discharge solutions for industry reduce environmental impact, recover water, and boost efficiency, ensuring sustainable industrial operations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

ZERO LIQUID DISCHARGE FOR INDUSTRIES: REDUCING ENVIRONMENTAL IMPACT AND BOOSTING EFFICIENCY

An Overview In today s era of environmental consciousness and stringent regulations, industries are increasingly turning to wastewater. One such advanced approach is Zero Liquid Discharge (ZLD) a wastewater treatment process that ensures no liquid waste is discharged into the environment. By recovering and reusing nearly all the water from industrial effluent, zero liquid discharge solutions for industry help minimize pollution while improving operational efficiency. sustainable solutions to manage

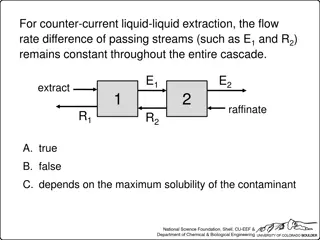

What is Zero Liquid Discharge (ZLD)? Zero Liquid Discharge is a comprehensive treatment method that involves processes like filtration, evaporation, and crystallization to treat industrial effluents. It focuses on recovering maximum water for reuse and converting the remaining waste into solid residues for safe disposal. Industries such as textiles, chemicals, power plants, and pharmaceuticals are increasingly adopting Zero Liquid Discharge Solutions for Industry to comply with environmental norms and reduce water dependency.

Environmental and Operational Benefits ZLD significantly reduces the risk of groundwater contamination and surface water pollution. By eliminating liquid waste discharge, industries help protect local ecosystems and comply with strict environmental regulations. Moreover, recovered water can be reused, reducing freshwater intake and lowering operational costs. In addition to ecological advantages, ZLD enhances a company s sustainability credentials, an increasingly important factor for stakeholders and consumers. It also fosters long-term savings by minimizing reliance on external water sources and reducing waste disposal expenses.

Embracing a Sustainable Future While ZLD systems may require a higher initial investment, the long-term returns in terms of environmental protection, compliance, and water savings make them a smart and sustainable choice. Embracing Zero Liquid Discharge Solutions for Industry is a proactive step toward a greener, water-secure future.

Embracing a Sustainable Future While ZLD systems may require a higher initial investment, the long-term returns in terms of environmental protection, compliance, and water savings make them a smart and sustainable choice. Embracing Zero Liquid Discharge Solutions for Industry is a proactive step toward a greener, water-secure future.

THANKYOU Contact Us +1-720-222-4739 info@r3sustainability.com www.r3sustainability.com