Improving Heat Rate Efficiency at Illinois Coal-Fired Power Plants

Heat rate improvements at coal-fired power plants in Illinois are crucial for enhancing energy conversion efficiency, reducing carbon intensity, and minimizing pollution. By increasing the heat rate/efficiency by 6%, these plants can generate more electricity while burning the same amount of coal. The concept of heat rate, its calculation, and the reasons for pursuing heat rate improvements are explained. Studies have shown that upgrades and best practices can lead to significant improvements in heat rate, offering a promising avenue for lowering carbon intensity in power generation.

Improving Heat Rate Efficiency at Illinois Coal-Fired Power Plants

PowerPoint presentation about 'Improving Heat Rate Efficiency at Illinois Coal-Fired Power Plants'. This presentation describes the topic on Heat rate improvements at coal-fired power plants in Illinois are crucial for enhancing energy conversion efficiency, reducing carbon intensity, and minimizing pollution. By increasing the heat rate/efficiency by 6%, these plants can generate more electricity while burning the same amount of coal. The concept of heat rate, its calculation, and the reasons for pursuing heat rate improvements are explained. Studies have shown that upgrades and best practices can lead to significant improvements in heat rate, offering a promising avenue for lowering carbon intensity in power generation.. Download this presentation absolutely free.

Presentation Transcript

Heat Rate Improvements at Illinois Coal-Fired Power Plants Jim Ross Manager, Division of Air Pollution Control Illinois EPA

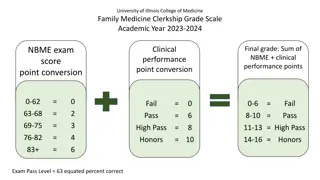

Building Block 1 Step 2 Building Block Goal (lbs % Reduced Cumulative % CO2/MWh) BB#1 Heat Rate/Efficiency Improvements at Coal-Fired EGUs Baseline 1,895 1 2 3 4 1,784 6% 6% Total 6% Coal-fired EGUs take actions to increase the heat rate/efficiency by 6% so that generate more electricity while burning same amount of coal 2

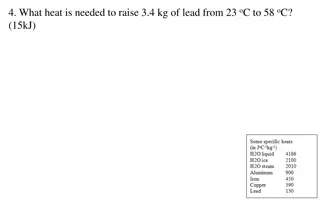

What is Heat Rate? Heat Rate (HR) = the efficiency of conversion from coal input to energy output HR = F/E F = heat energy input supplied by coal in Btu E = energy output from the EGU in kWh The efficiency is calculated by dividing the equivalent Btu content of a kWh of electricity (which is 3,412 Btu) by the heat rate. For example, if the heat rate is 10,140 Btu/kWh, the efficiency is 34%. Heat content of coal = mmBtu/ton of coal (varies by coal type) The amount of coal used to generate electricity depends on the efficiency or heat rate of the EGU and the heat content of the coal. EGU efficiencies/heat rates vary by type and size of EGU, age of EGU, coal type, emission controls, and other factors.

Why Heat Rate Improvements? changes can be made that increase the efficiency of an EGU in converting coal to energy. Less amount of coal burned to produce an amount of electricity Desirable because results in less pollution per amount of coal burned = less carbon intensity The lower the heat rate the better, i.e., more power is produced per amount of coal burned (since generation is in denominator) Lower heat rate = higher efficiency

USEPA Basis for Heat Rate Improvement Reviewed several studies, in particular 2009 Sargent and Lundy examined specific best practices and equipment upgrades, including upgrades to boilers, steam turbines, and control systems .. 4 to 12 percent improvement possible 1. Reviewed historical heat rate data. Identified several data apparent instances where an EGU's heat rate experienced a substantial improvement in a short time presumably because of equipment upgrades installed at that point in time . 3 to 8 percent possible 2. Conclusion: strong basis for considering heat rate improvement as a meaningful potential approach to reducing the carbon intensity of generation at individual affected fossil fuel-fired EGUs.

Heat Rate Improvement Areas and Amounts 2 principal areas of analysis: 1. Best Practices: improvements that could be achieved by reducing heat rate variability at individual coal-fired EGUs through adoption of best practices for operation and maintenance 2. Equipment Upgrades: improvements that could be achieved through further equipment upgrades

HR Improvements (cont.) Best Practices to operating and maintenance procedures: 1. assessed variability in hourly gross heat rates of approximately 900 individual coal-fired EGUs from 2002 to 2012 Found heat rate variability relative to average heat rates and deviations generally result in performance worse than the optimal heat rates (reduce variability improve heat rate) 1.3 percent to 6.7 percent potential for improvement in the average heat rate of entire fleet of coal-fired EGUs Conclusion: reasonable estimate for purposes of developing state- specific goals is that affected coal-fired steam EGUs on average could achieve a four percent improvement in heat rate through adoption of best practices to reduce hourly heat rate variability 4%

HR Improvements (cont.) 2. Equipment Upgrades: evaluated potential opportunities through specific upgrades identified in the 2009 Sargent & Lundy study implementation of full subset of appropriate opportunities at a single EGU could be expected to result in heat rate improvement of ~ 4 percent recognize that this may overstate the average equipment upgrade opportunity across all EGUs because some EGUs may have already implemented some of these upgrades - on average across the fleet of affected EGUs, only 1/2 of the full equipment upgrade opportunity remains x 4% = 2%

1. Best Practices = 4% 2. Equipment Upgrades = 2% Total Potential for Heat Rate Improvement = 6% Building Block 1

Docket ID No. EPA-HQ-OAR- 2013-0602 GHG Abatement Measures USEPA Technical Support Document (TSD)

How Improve? Minimizing heat loss is the greatest factor affecting the loss of efficiency Equipment refurbishment Plant upgrades Improved operations and maintenance schedules 1) 2) 3) 4)