Creep Behavior in Metallic Materials

Typical creep tests subject specimens to constant stress at elevated temperatures, revealing primary, secondary, and tertiary creep stages. Cavitation phenomena in the tertiary region lead to rupture, motivating the development of single crystal alloys. Design parameters focus on measuring steady-state creep rate and rupture life under varying stresses and temperatures.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

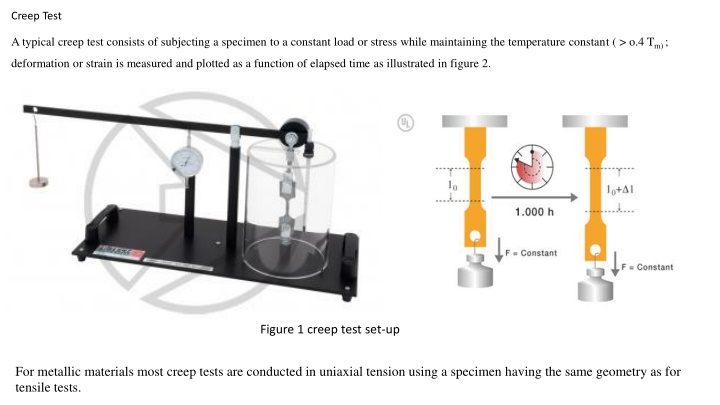

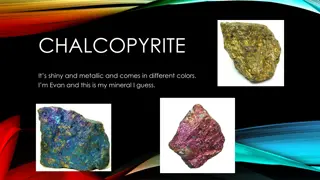

Creep Test A typical creep test consists of subjecting a specimen to a constant load or stress while maintaining the temperature constant ( > o.4 Tm) ; deformation or strain is measured and plotted as a function of elapsed time as illustrated in figure 2. Figure 1 creep test set-up For metallic materials most creep tests are conducted in uniaxial tension using a specimen having the same geometry as for tensile tests.

Fig (2) Typical creep curve of strain versus time at constant stress and constant elevated temperature

Creep Stages: Following the instantaneous deformation (elastic region), there are three stages: 1-Primary Creep: starts at a rapid rate as a result of dislocations movements and slows with time due to the work hardening (low temperature) which ties-up the dislocations at grain boundaries. 2- Secondary Creep: has a relatively uniform strain rate due to the balance between work hardening and annealing (thermal softening). This is often the stage of creep that is of the longest duration 3- Tertiary Creep: has an accelerated creep rate and terminates when the material breaks or ruptures. This acceleration due to with the formation of voids and micro-cracks at grain boundaries.

Cavitation Phenomenon: - In tertiary region, rupture occurs due to the pore formation (cavitation) at grain boundaries. - Cavities form on grain boundaries that are perpendicular to the applied force - Eliminating the grain boundaries altogether should enhance the creep-rupture life - This was the motivation for developing single crystal alloys. Figure -3- Cavity coalescence at grain boundaries

Design Parameters Most important design parameters in creep are: Measure Steady state creep rate Measure Rupture life time tr (stress rupture test). Similar to creep test except the stress is higher Note: both of designs strongly depend on temperature and stress applied Creep Test. Stress Rupture Test Measures strain versus time at constant temperature and load or stress Measures stress versus time to rupture at constant temperature Relatively low loads and creep rates. Higher loads and creep rates Long duration, 2,000 to 10,000 hours. Not always to fracture .... Shorter duration, less than 1,000 hours typically. Always to fracture Strain measured accurately using sensitive equipment (inductance determine creep rate. Strains typically less than 0.5%. Simpler less sensitive strain measuring equipment (dial gauges). Time and strain to fracture measured. Strains typically up to 50%. gauges) to

Data extrapolation method One of the most popularly used techniques in representing creep-rupture data is Larson-Miller Time temperature parameters. This parameter can be derived from the stress and temperature dependence of the creep rate or time to rupture. The rate equation generally can be written in the form of the Arrhenius equation and expressed as PLM= T [C + log (tr)] where C is a constant (usually on the order of 20), for T in Kelvin and the rupture lifetime in hours, PLM is Larson-Miller parameter. Example: Using the Larson Miller data for S-590 iron shown in Figure 4, predict the time to rupture for a component that is subjected to a stress of 140 MPa at 800 C Solution From Figure 4 , at 140 MPa the value of the Larson Miller parameter is 24x103 , for T in K and in h; therefore, 24x103 = T [C + log (tr)] 24x103 = ( 800+273) [ 20+ log (tr)] 20+ log (tr) = 22.37 tr= 233hour (9.7 days).

Figure -4- Logarithm stress versus the LarsonMiller parameter for an S-590 iron.

Design Considerations to avoid Creep Reduce the effect of grain boundaries: Use single crystal material with large grains. Addition of solid solutions to eliminate vacancies. Employ materials of high melting temperatures. .