Critical LOTO Equipment That Transforms Safety on the Industrial Workplace

Workplace safety is not just a compliance requirement - itu2019s the backbone of efficient and productive operations. In environments where machinery, electricity, steam, and pressurized systems are used daily, controlling hazardous energy is critic

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

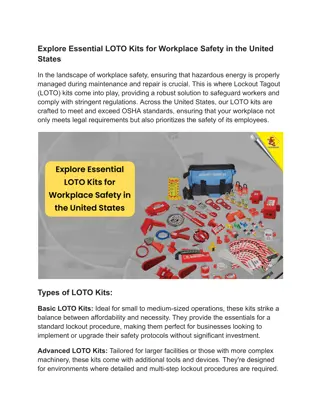

Critical LOTO Equipment That Transforms Safety on the Industrial Workplace Workplace safety is not just a compliance requirement - it s the backbone of efficient and productive operations. In environments where machinery, electricity, steam, and pressurized systems are used daily, controlling hazardous energy is critical to preventing accidents. The Lockout Tagout system has long been recognized as the gold standard for isolating energy sources and protecting workers during maintenance or servicing activities. But the effectiveness of a LOTO program depends on more than written procedures. It relies heavily on the right LOTO equipment - the tangible tools that physically secure energy-isolating devices and communicate vital safety information. The following are the critical pieces of LOTO devices that can truly transform safety in the industrial workplace.

1- Lockout Safety Padlocks At the heart of every LOTO procedure lies the lockout padlock. Unlike conventional padlocks, these are designed specifically for safety applications, often made from non-conductive, lightweight materials such as ABS or aluminum. Key benefits include: Individual Accountability: Each worker uses their own padlock, ensuring only they can remove it. Color Coding: Helps identify departments or maintenance teams. Durability: Resistant to corrosion, heat, and harsh industrial environments. Using the right lockout padlock ensures that machines cannot be restarted until maintenance is safely completed. 2- Lockout Hasps Many maintenance operations involve multiple workers servicing a single machine. Lockout hasps allow several padlocks to be applied to one energy isolation point, ensuring that equipment cannot be re-energized until every individual has removed their lock. Benefits of using hasps: Supports group maintenance activities. Encourages teamwork and clear accountability. Available in steel, aluminum, and non-conductive nylon for various environments. 3- Valve Lockout Devices

Valves are a common source of hazardous energy, controlling liquids, gases, and steam. Valve lockout devices prevent accidental opening by physically blocking the valve handle or handwheel. Types include: Ball Valve Lockouts - Secure quarter-turn valves in the "off" position. Gate Valve Lockouts - Completely enclose handwheels to stop unauthorized access. Butterfly Valve Lockouts - Clamp around the handle to immobilize it. These devices are indispensable for industries like oil and gas, chemical processing, and food manufacturing where fluids under pressure pose a significant hazard. 4- Circuit Breaker and Electrical Lockouts Electrical hazards are among the most dangerous in the workplace. Circuit breaker lockouts prevent breakers from being switched on during maintenance. Plug lockouts, wall switch lockouts, and electrical panel lockouts further ensure that electricity remains isolated.

Key advantages: Reduce the risk of electric shock and arc flash. Fit a wide range of breaker types and sizes. Provide visual assurance that circuits are safely de-energized.

5- Lockout Tags While physical devices prevent energy flow, lockout tags provide crucial communication. They display information such as the name of the person who applied the lock, the reason for the lockout, and the date. Benefits: Increases visibility and awareness. Prevents unauthorized removal of locks. Available in durable, tear-resistant, and weatherproof materials. 6- Lockout Stations and Kits Having the right equipment is only effective if it is organized and accessible. Lockout stations and portable kits ensure that padlocks, tags, hasps, and other devices are available where and when they are needed. This reduces delays, standardizes procedures, and improves overall safety culture.

Conclusion A safe industrial space is the result of preparation, awareness, and the consistent use of reliable safety tools. Critical LOTO devices - padlocks, hasps, valve lockouts, breaker lockouts, tags, and stations - provide a robust defense against hazardous energy incidents. By equipping workers with the right tools and ensuring they are trained to use them correctly, organizations can transform workplace safety from a reactive process into a proactive culture. Investing in proper LOTO equipment doesn t just protect employees - it protects productivity, compliance, and ultimately, the reputation of the business.