Design of a Lightweight Mounted Tip/Tilt Mirror

This document presents the design considerations for a lightweight mounted tip/tilt mirror by Mike Borden. It outlines various design problems, materials, and manufacturing considerations such as stiffness-to-weight ratios and thermal stresses. The analysis includes a comparison of materials like ULE, Zerodur, and aluminum, and discusses optimal optical specifications, including surface roughness and error budgets for mirror performance.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Design of a Lightweight Mounted Tip/Tilt Mirror MIKE BORDEN OPTI 523 4/6/09

To Do List Type of lightweight Mirror material and coating Linear actuator Mount and flexure design

Lightweighting Contoured Back Sandwich, and Open Back

Mirror Material Considerations High stiffness to weight Ease of manufacture Minimal thermal stresses Cost Main materials being considered ULE, Zerodur, Fused Silica, Beryllium, Aluminum, BK7

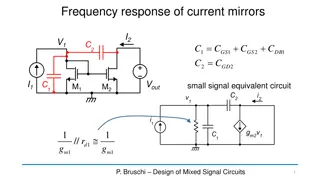

Mirror Material Substrate Comparison 160000 Stiffness to Weight (N/mm^2- 140000 120000 100000 kg) 80000 60000 40000 20000 0 ULE Zerodur Fused Silica Beryllium Aluminum BK7

Mirror Materials Open Back Mirror Deflection Curve 6 5 Deflection (nm) 4 ULE Zerodur Fused Silica Beryllium 3 2 1 0 0 10 20 30 40 50 60 70 80 90 100 Mirror Angle (deg)

Mirror Material Possibilities Pure Beryllium mirror Expensive and difficult to manufacture Thermal considerations non-issue Fused Silica, BK7, Aluminum substrate w/ silver coating Aluminum w/ silver coating provides smallest ? (23 ppm / K and 18.9 ppm/ K) Thermal expansion / contraction an issue Something crazier Copper, Brass, Beryllium Copper, Stainless

Optical Specifications Silver Coating Meets spectrum requirements

Optical Specifications Error Budget 30 nm rms WFE Mirror surface roughness ( S) 20 nm rms Self weight deflection ( ) 20 nm rms Beam diameter 200 mm diameter mirror accommodates 150 mm beam diameter

Mounting Concept Invar Sleeve Spherical Bearing Micrometer

Remaining Tasks Verify number of supports Reflectance of Be Tolerance bearings for thermal loading Flexure design dimensions, material FEA analysis of deflection / thermal loading, resonant frequency Linear actuator / micrometer selection