Innovative Turbo Installation System Enhancement

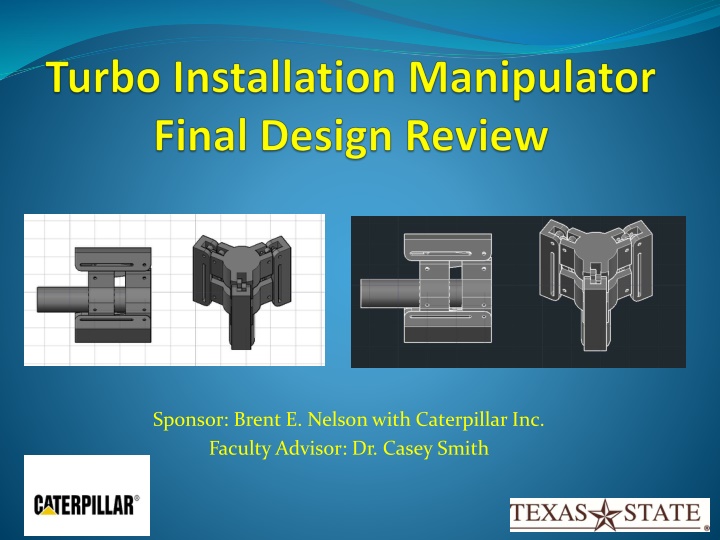

In this project sponsored by Brent E. Nelson with Caterpillar Inc., the team aims to address the issue of incorrect installation of interchangeable pucks. They have developed a one-size-fits-all device to ensure precise puck installation. The project includes block diagrams, design modifications, and successful prototypes with future plans for further enhancements. The innovative solution promises improved efficiency and accuracy in turbo installations.

Uploaded on Feb 24, 2025 | 1 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Sponsor: Brent E. Nelson with Caterpillar Inc. Faculty Advisor: Dr. Casey Smith

Project Overview Currently, the system involves interchangeable pucks. The main goal of our project is to make sure the wrong puck cannot be installed. To do this we have designed a one size fits all device to replace the pucks.

Project Motivation The problem: Pucks do not have a footprint or designated area Each puck is sized to only a few turbo part numbers

Top-Level Block Diagram Engine arrives at work station Team member uses GCI arm to lift the turbo Team member moves turbo to the engine Turbo is attached to engine and released from arm.

Design-Level Block Diagram Swing Arm closed and pressure plate depressed Moves GCI arm to turbo Gripper is expanded pneumatically GCI arm is moved back to the home Turbo is moved to the engine and installed Release the turbo

Results Air bladder design was dropped and a new mechanical linear actuator gripper was designed and prototyped Air logic was incorporated with PLC logic

Results Cont. Prototype provides proof of concept (Adjustable to all diameter ranges) Max Diameter of Turbos: 137mm Min Diameter of Turbos : 65mm Max Diameter of Gripper: 148mm Min Diameter of Gripper: 62mm Fits depth of all turbos: 10-25mm

Future Work Changes Reasoning Use of nuts, bolts, and sleeves to hold the elements of the gripper together. This would make the device more stable and reliable Prototype design using a metal or high strength material Prototype would be a proof of concept using a new manufacturing method. Modify particular dimensions of gripper for manufacturing into a new material This would need to be done in order to satisfy metal manufacturing which is completed using a different process as well as strength of material Move the holes in which the nuts and bolts will be inserted, farther away from any edges Allow for less force to be exerted towards breaking points. Design a pressure plate Plate would control a sensor that would not expand until gripper is a minimum distance inside the turbo

Acknowledgments Brent Nelson Caterpillar Inc. Ryan Melvin Caterpillar Inc. Dr. Casey Smith Faculty Advisor Dr. Compeau