Modelling induction heating of Modelling induction heating of ionic solutions using COMSOL ionic solutions using COMSOL

In this study, Dr. M.J. Taylor explores the induction heating process of ionic solutions using COMSOL. The research focuses on the interaction of alternating magnetic fields with electrically conducting materials to induce eddy currents, leading to resistive heating. The specific power transferred via induction heating is mathematically approximated, considering factors such as magnetic flux density, frequency, electrical conductivity, material length, and density. Frequencies ranging from 2 MHz to 40 MHz are investigated, with experimental validation challenging at megahertz frequencies. The study utilizes the AC/DC model in COMSOL to conduct a 3D frequency-transient analysis, aiming to validate the theoretical equation and determine the value of the geometrical correction factor, k, for different material geometries. Various study conditions involve ionic solutions of differing shapes and concentrations placed between Helmholtz coil pairs with a homogenized multi-turn configuration. Electromagnetic heating is coupled with the magnetic field and heat transfer equations in the simulation model.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Modelling induction heating of Modelling induction heating of ionic solutions using COMSOL ionic solutions using COMSOL Dr M J Taylor CPhy FInstP Perpetual Research Consultancy Ltd

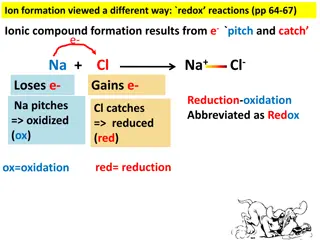

Induction heating Induced eddy currents in electrically conducting material, with power transfer due to resistive heating Alternating current through a coil Alternating magnetic field Eddy currents are orthogonal to the direction of the magnetic field One orthogonal plane (e.g. thin wires) mean one degree of freedom for eddy currents Two orthogonal planes (e.g. tiles) mean two degrees of freedom for eddy currents

Frequencies usually below 500 kHz, but new applications require frequencies in excess of 40 MHz Such applications include heating low conductivity ionic solutions and polymers where microwave heating cannot be used High-frequency magnetic field heating zone Magnetic field generator

The specific power transferred via induction heating can be described by a numerical approximation: Equ (1) B B is the peak magnetic flux density (T) f f is the frequency of the magnetic field (Hz) s sis the electrical conductivity of the material ( -1 m-1) ? is the length of the material in the orthogonal direction (m) D D is the density of the material (kg/m3) k k is a geometrical correction factor thought to equal 1 for 1 degree of freedom, or 2 for 2 degrees of freedom

Experimental validation is difficult at megahertz frequencies Equ (1) So the AC/DC model of COMSOL has been used in a 3D frequency-transient study The aim of this study was to validate the equation, and determine the value of k k for different geometries, for frequencies from 2 MHz to 40 MHz

Study conditions Ionic solution (e.g. saline) of various shapes and concentrations centrally located between the coils Helmholtz coil pair Homogenized multi- turn with 10 turns Extremely-fine, free tetrahedral mesh Normal mesh Current through the coils varied to alter the magnetic field strength Electromagnetic heating coupled to the magnetic field and heat transfer equations

The uniformity of the magnetic field in the vicinity of the saline had a variance of 0.12% Study conditions The simulations were run for 10 s in 500 ms time-steps Each simulation took a minimum of 120 s to execute, which increased to over 3 hrs as the saline sample size decreased

Equ (1) can be re-arranged to give the heating rate of an inductively heated body 2?2?2) ?? ? ?= ?(??? Equ (2) where cis the specific heat capacity of the material being heated, and ? = ?2/6? 2?2?2) (??? A plot of ? ought to give a straight line with gradient , ?against ?? allowing ? to be determined for a range of situations

Saline cylinder, axis parallel to magnetic field ? = ?2/6? = 0.619 This gives a value ? = 2.66 1/3rd higher than previously thought for thin cylinders Therefore heating rates will be 1/3rd lower than previously thought

Previous value for k Results summary 1 1 2 2 2 2 2

Experimental validation Inductive heating tests at 2 MHz undertaken courtesy of Trumpf H ttinger GmbH, Freiburg

Experimental validation A 2D axi symmetrical frequency-transient study simulated tests An extremely fine, physics-controlled mesh was used in 1 s time steps for 10 s Inductive heating tests at 2 MHz undertaken courtesy of Trumpf H ttinger GmbH, Freiburg

Experimental validation Magnetic flux density Temperature Non uniformity of the magnetic field significantly increases non uniformity of heating Stirring can be artificially accomplished by changing the thermal conductivity from 0.5918 W/m.K to a very high value (104 W/m.K)

Experimental validation Magnetic flux density Temperature Temperature Non uniformity of the magnetic field significantly increases non uniformity of heating Stirring can be artificially accomplished by changing the thermal conductivity from 0.5918 W/m.K to a very high value (104 W/m.K)

Experimental validation Magnetic flux density Temperature Experimental heating rate of T/ t = 0.33 C/s compares favourably to simulation T/ t = 0.34 C/s

Conclusions High-frequency, low strength magnetic field heating zone Magnetic field generator COMSOL has deepened our understanding of high-frequency magnetic induction heating of low-conductivity fluids Work is in progress to validate the model up to 1 GHz

Thank you Questions?