Operating Costing in Commerce

Discover the meaning, objectives, and processes of operating costing in commerce, including job costing and process costing. Learn how it helps in cost management and efficiency improvement.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

OPERATING COSTING M.VIJAYASEKARAM LECTURER IN COMMERCE S.V.C.R.GOVT DEGREE COLLEGE PALAMANER

MEANING OF OPERATING COSTING Operating ascertainment of cost for providing a standardized service to the public or to an undertaking. costing is a process and technique of accumulating and Definition of Operating Costing ICMA, London, Operating costing is that form of operation costing which applies where standardized services are provided either by an undertaking or by a service cost center within an undertaking. Wheldon, Operating costing is actually unit costing as applied to the costing of services.

OBJECTIVES OF OPERATING COSTING The objectives of operating costing are listed below: 1. To supply the information through which the efficiency in rendering service is improved. 2. To provide a basis for fixing accurate quotation and fare. 3. To ensure that the services are provided in proper time. 4. To control the fuel consumption and its expenses. 5. To ensure that the service equipments are properly maintained. 6. To provide cost comparison between own service and alternative service i.e. hiring. 7. To compare the cost of one service center with another. 8. To determine the apportionment cost if the services are provided within an organization. 9. To decide the price that can be charged for use of vehicle. 10. To control the cost of maintenance and repairs. 11. To select efficient and suitable routing of vehicles to reduce the costs to production departments that uses the service. 12. To avoid the under utilization of capacity and idle time of the work force. 13. To absorb the fixed costs proportionately and systematically that is allocated to the units of services.

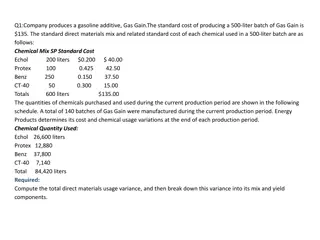

PROCESS COSTING The first component of operation costing is process costing. Process costing is the costing method used when products are produced with very few differences, and those differences aren't assigned a specific cost difference. So with process costing, each product is given the same cost. Process costing is common in certain manufacturing environments. For example, it would be unduly costly if a company determined the cost of each gallon of gas produced, each hamburger made, and each bag of cat food created. When Tri-Lock produces its keys, there are slight differences in the keys, but the differences are so small there's no benefit to assigning them different costs. Therefore, they are all given the same cost due to process costing.

JOB COSTING The other important piece of operation costing is job costing. Job costing is an accounting method that calculates and assigns the costs of labor, materials, and overhead to a particular job. This type of costing requires detailed accounting for each type of input. Let's take a look at each of these types of input a little closer: For materials, costs are assigned to each component when it is used in the manufacturing of a good. The brass and steel used in the manufacturing of locks would fall into this category. For labor, costs of employee wages are included in labor and assigned to a specific job. The labor used to machine the locks is accounted for under labor. For overhead, the costs are included to account for business expenses like electricity, heat, communications, and insurance. They must be partitioned out to be assigned to a job.