Understanding Optical Fiber Fabrication Process

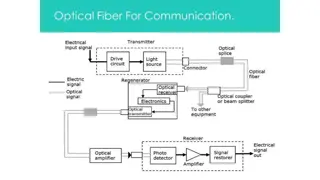

Discover the multi-step fabrication process of optical fibers, from preform fabrication to fiber drawing, coating, and spooling. Learn about the materials used, such as glass fused silica, halide gases, rare earth doped glass, and polymer, for efficient signal transmission in telecommunications and internet communication. Explore the properties, applications, and benefits of optical fibers in long-distance signal transmission with low attenuation and high security.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

OPTICAL FABRICATION hackatronic.com

PRESENTED BY DEEPCHANDRA PRAJAPATI(15) ROSHAN SINGH(24) MAYUR PAGARE(09) SHIVAM SINGH(26)

WHAT IS OPTICAL FIBER ?? An optical fiber is a flexible, transparent fiber made by drawing glass (silica)or plastic to a diameter slightly thicker than that of a human hair. Optical fibers are used most often to transmit light between the two ends of the fiber and find wide usage in fiber-optic communications.

Large bandwidth, smaller diameter, light weight, long distance signal transmission, low attenuation, transmission security WHY & WHERE ?? To transmit telephone signals, Internet communication, and cable television signals

Optical Fibers are Fabricated in a Multi-Step Process Preform Fabrication FABRICATION Fiber Drawing Fiber Coating Spooling.

It should be possible to draw Flexible Thin Kilometer Longs fibers from Material Since Core and Cladding are different materials, we should use two physically compactible materials should be available to make theme. REQUIREMENTS The Materials should have as low loss as possible.

GLASS Fused Silica or Silicate Glass Mostly used for telecommunication Low loss, chemical inertness, high Stability, resistant to deformation at high ambient temperature

HALIDE GASES Major Components ZrF4 other components CaF2 , CaF3, AlF3, and NaF. Extremely low transmission losses at Mid-IR wavelength Potential Component for futuristic OFC System 2um. Fluoride Glass

Rare Earth Doped glass Doping of Er/Nd/Tm in Fused Silica Used for making optical fiber amplifier & Lasers ACTIVE GLASS

POLYMER Poly(Methyl, Methaacrylate)/ Per Fluorinated Polymer High losses (0.2dB/m) Low Cost, Easy handling, Light Weight Fiber Dimensions Much larger than glass fiber Less expensive components Short distance communication(i.e. up to 100m), illumination & Sensing

FIBER FABRICATION FABRICATION OF PREFORM DRAWING FIBER FROM THE PREFORM

FABRICATION OF PREFORM STARTING CHEMICALS (SiCl4, GeCl4, POCl3, SiF4, PCl3) Chemical Vapour Deposition Flame Hydrolysis VAD MCVD OVPO/OVD PMCVD PCVD (Vapour Axial Deposition) (Modified Chemical Vapour Deposition) (Outside Vapour Phase Oxidation or Outside Vapour Deposition (Plasma Modified CVD) (Plasma Activated CVD) Two most popular Techniques are OVPO/OVD MCVD

OVD(Outside Vapour deposition) SiCl4, GeCl4, BCl3 React with O2 with help of hot flame Soot Preform - Deposited on Ceramic Rod (Mandrel) - Keep Rotating, Deposition takes place Evenly Changing % of Dopant Material R-I can be Adjusted Preform Removed From Rod - Placed in High Temperature furnace - Converted to Solid mass Material -: Sintering Different Fiber Strand Can Be drawn

MCVD(Modified Chemical Vapour Deposition) Pure Liquid Reactant Glass Chamber Inert Gases Added to it Vapour Heated Using OXY HYDROZEN FLAME Silica Tube Flame is Kept Moving Back & Forth

Soot is Deposited Inside walls of the Tube. Sintering takes place inside. Changing Mixture of Chemical Vapours Heated R-I Adjusted Tube Collapses Solid Glass Rod 1900 C

DRAWING FIBERS Pulling of Softens Preform into to Thin Glass Filaments Melting of Ends Feeding Glass Preform

APPLICATION Communication Broadcasting Defense Lighting and Decorations Industries Medical Industry Mechanical Inspections Ability to Conduct Light Under Water

CONCLUSION Manufacturing Process. Various Method for Manufacturing of Optical Fiber. Limitation of Optical Fiber Design . Timeline , Budget, Tolerance.