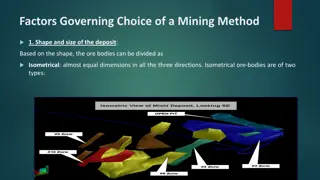

Steps in Ore Exploitation Process

The exploitation of ore involves key steps from mineral exploration to marketing the metal. Factors like ore grade and cut-off grade impact the economic evaluation of ore deposits. Other factors, such as by-products and mineralogical form, also play a crucial role in determining the value of cut-off grade.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

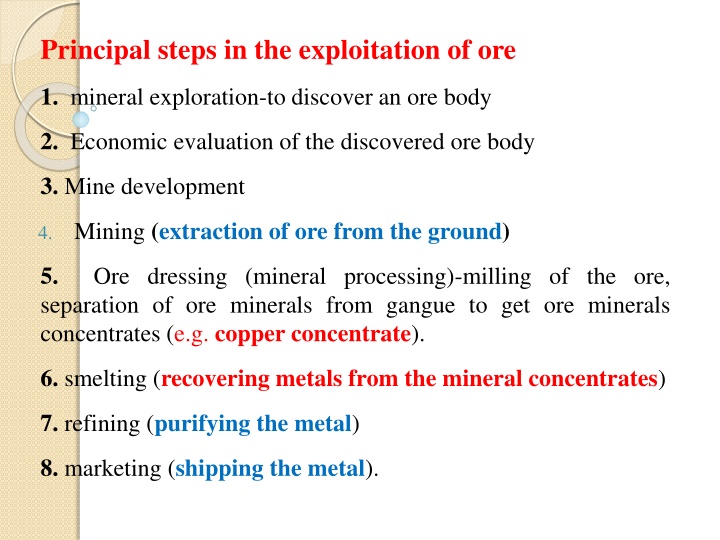

Principal steps in the exploitation of ore 1. mineral exploration-to discover an ore body 2. Economic evaluation of the discovered ore body 3. Mine development Mining (extraction of ore from the ground) 4. 5. separation of ore minerals from gangue to get ore minerals concentrates (e.g. copper concentrate). Ore dressing (mineral processing)-milling of the ore, 6. smelting (recovering metals from the mineral concentrates) 7. refining (purifying the metal) 8. marketing (shipping the metal).

Some important factors in the economic evaluation of ore deposit Ore grade: The concentration of a metal in an ore body, usually expressed as a percentage or in parts per million (ppm). Cut-off grade: The lowest grade of ore that can be extracted with the highest profit. The value of cut-off grade varies from one ore deposit to another and within the same metal depending on many geological and non-geological factors

Factors affecting the value of cut-off grade 1- By-product In some ores several metals are present and the sale of one may help and is enough to extract the other. For example, silver and cadmium can be by-products of the mining of lead-zinc ores and uranium is an important by-product of many South African gold ores. 40% of the gold recovered at U.S.A is by-products in the extraction of copper ore.

2- Mineralogical form The properties of a mineral affect the ease with which existing technology can extract and refine certain metals and this may affect the value of cut-off grade. Nickel is recovered far more readily from sulphide than from silicate ores, and sulphide ores can be worked down to about 0.5% whereas silicate ores must assay about 1.5% in order to be economic. The mineralogical nature of the ore will also place limits on the maximum possible grade of the concentrate. For example, in an ore containing native copper it is theoretically possible to produce a concentrate containing 100% Cu ,but if the ore mineral was chalcopyrite (CuFeS2) ,the principal source of copper, then the best concentrate would contain only 34.5% Cu.