Activated Hydrochar from Paddy Straw for Nutrient Adsorption and Water Management

Explore the development of activated hydrochar from paddy straw for effective nutrients adsorption and crop water management. Learn about the advantages of hydrochar over biochar, its production mechanism, and the justification for its implementation in Sri Lanka to address crop water management challenges. Discover the objectives of the study and the potential applications of hydrochar in agriculture.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

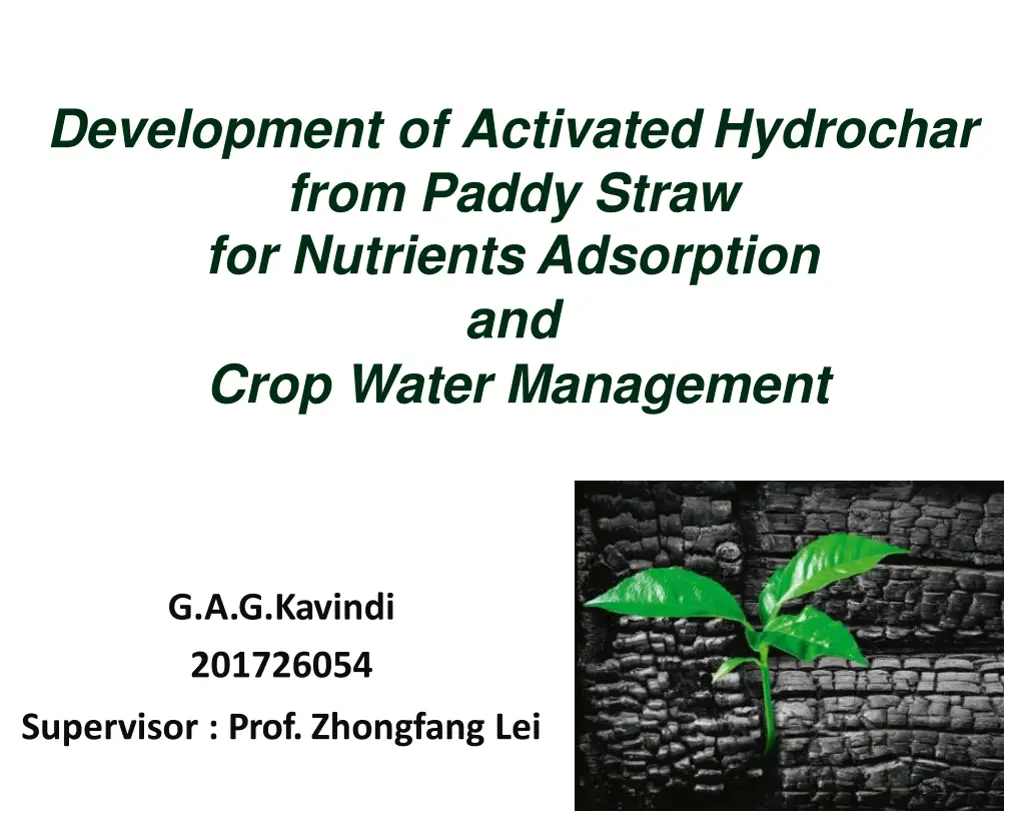

Development of Activated Hydrochar from Paddy Straw for Nutrients Adsorption and Crop Water Management G.A.G.Kavindi 201726054 Supervisor : Prof. Zhongfang Lei

Content Paddy straw Hydrochar Mechanism Justification Objectives Material andMethodology Result and Discussion Conclusion Future studies References 2

Paddy Straw Paddy - world s third largest cereal crop Rice - Staple of Sri Lanka paddy straw is abundantlignocellulose waste material Total straw production in Sri Lanka 3.4 million tonnes/year Uses - paper production constructionmaterials compost energysource animal feed Burning in the fields- cost-effectivebut environment pollution Source: www.newsclick.in3

Hydrochar Paddy straw hydrochar - reduce cropwaste generation Reduce CO2 emission with carbonsequestration Hydrochar production- hydrothermal carbonization process under subcritical water condition Characteristics microporosity ion exchange capacity water holding capacity large specific surfacearea low H:C and O:C ratios 4

Mechanisms Source : Oliveira et.al, 2017 5

Hydrochar Advantages over Biochar Cost Effective due to less energy consumption Applicable for wet biomass Applications Moisture conservation technique Soil conditioner (saline and acidicsoil) Improve soil Bulk density (Crop and root growth) Enhance microbial growth Removal of Hazardous chemicals Renewable energy production 6

Justification In Sri Lanka annual rainfall decrease and irregular rainfall cause crop water management problems Degradation of arable lands and population growth Crop intensification Limitations of nutrient availability (Phosphorus) Leachate of nutrients Agriculture responsible for eurtophication Required proper moisture conservation and nutrient management techniques Source: www.open.edu 7

Objectives Determine the P and N adsorption capacity ofthe produced hydrochar To determine the water holding capacity of hydrochar as a moisture conservationtechnique Optimal procedures for hydrochar production from paddy straw 8

Materials and Methodology Hydrochar production 10 g Paddy straw : 100 ml DW 1:10 w/v HTC temperature ( C) 100 200 250 HTC holding time (min) 0 Hydrothermal Reactor Capacity 200ml 60 120 T1 T4 T7 T2 T5 T8 T3 T6 T9 9

Methodology Parameter Methodology Yield M hydrochar/M paddy straw*100 pH meter pH EC EC meter Bulk Density Weight of sample (g)/ Volume of sample (ml)*100 (M2-M/M1-M) *100 (M1- initial wt,M2- wt after absorption, M- wt ofcontainer) Moistureabsorption capacity Volatile matter content Muffle furnace at 600 0C for 4 hrs Nutrientadsorption Batch adsorption test and adsorption isotherm 10

Result and Discussion Table 1 : Hydrochar yield, Bulk density and Solid percentage Ash + Fixed carbon (%) 12.0 12.0 14.0 11.8 16.0 18.0 22.0 22.0 28.0 30.0 HTC Holding Time (min) Bulk density (%) Volatile Matter (%) Yield (%) Temperature (0C) T0 T1 T2 T3 T4 T5 T6 T7 T8 T9 paddy straw 100 100 100 200 200 200 250 250 250 - 18.9 14.6 15.2 14.9 15.3 16.8 14.2 29.5 39.0 33.0 88.0 88.0 86.0 88.2 84.0 82.0 78.0 78.0 72.0 70.0 0 81.5 81.5 81.4 78.2 60.1 58.2 56.5 50.5 45.0 60 120 0 60 120 0 60 120 11

Result and Discussion With increasing temperature and holding time, Yields declined and rapid decline observed above 2000C Bulk Density decreased compared tofeedstock Porosity tend to increase with increasingtemperature Contrary Higher bulk density observed at 2500C Volatile matter content decreased with organic matter removal Fixed carbon content increased with breakage of lignocelulose T0- paddy straw T4 200 0C, 0 min T7- 250 0C, 0 min T8- 250 0C,60 min T9 -250 0C, 120min Figure 1: Hydrochar at different temperature and exposing time 12

Result and Discussion Table 2 : Hydrochar pH and Electrical conductivitychanges Temperature (0C) Time (min) pH EC (ms/cm) 7.7 6.5 6.3 5.6 5.1 4.8 5.7 5.4 5.8 5.1 2.76 2.48 2.69 2.86 3.30 4.50 2.11 3.02 3.82 3.63 T0 T1 T2 T3 T4 T5 T6 T7 T8 T9 paddy straw 100 100 100 200 200 200 250 250 250 0 60 120 0 60 120 0 60 120 13

Result and Discussion pH Change from neutral to Slight acidic condition Minimum pH in (T5)200 0C for 60 minute holding time EC increased with increasing temperature Maximum EC observed for T5 followed by T8 EC and pH depend on production process and feedstock type pH and EC is important as per the application Figure 2: Prepared hydrochar samples for pH and EC measurement 14

Result and Discussion 6 T0- paddy straw T1- 100 C, 0min T2-100 C, 60min T3-100 C,120min T4-200 C, 0min T5-200 C, 60min T6-200 C,120min T7-250 C, 0min T8-250 C, 60min T9-100 C,120min Moisture absorption rate (g/1gof 5 4 hydrochar) 3 2 1 0 0 5 10 15 20 25 30 Time(hours) Figure3 : Moisture absorption rate of different hydrochar over time Maximum absorption T5 5.39 g/ 1g of hydrochar followed by 5.17 g/ 1g of hydrochar T9 Minimum absorption feedstock- 2.41 g/ 1g of hydrochar Water holding capacity increase with increasing porosity Micro-pores and meso-pores are responsible for water holding 15

Conclusion Char Yield negatively correlated with HTC temperature Least yield 45% at T9- (250 0C 120minutes) Lowest pH (4.8) and maximum EC (4.5 ms/cm) in T5 (200 0C for 60 minutes) Maximum Water holding capacity in T5 - 5.39 g/ 1g of hydrochar Water holding capacity two times higher than feedstock Total pore volume of hydrochar increase with increasing HTC temperature T5 most suitable hydrochar type as moisture conservation measure 16

Future Studies Determination of the P and Nadsorption capacity of the producedhydrochar Study the P and N adsorption kinetics and Isotherms 17

Figure 4: Hydrochar at moisture absorption test Figure 5: Hydrochar samples after drying 18

References Ahmad, M., Rajapaksha, A. U., Lim, J. E., Zhang, M., Bolan, N., Mohan, D., Ok, Y. S. (2014). Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere, 99, 19 23. Oliveira, F. R., Patel, A. K., Jaisi, D. P., Adhikari, S., Lu, H., & Khanal, S. K. (2017). Environmental application of biochar: Current status and perspectives. Bioresource Technology, 246(August), 110 122. Qambrani, N. A., Rahman, M. M., Won, S., Shim, S., & Ra, C. (2017). Biochar properties and eco-friendly applications for climate change mitigation, waste management, and wastewater treatment: A review. Renewable and Sustainable Energy Reviews, 79(November 2016), 19

Thank You 20