Application of NIR Spectroscopy in Molasses Desugaring Process

"Explore the efficient use of Near-infrared Spectroscopy (NIRS) for detecting sucrose and betaine in molasses desugaring process using chromatographic methods. Learn about the separation loops, measurement range, and steps to build an accurate NIR prediction model."

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Application of Near-infrared Spectroscopy (NIRS) for the Detection of Sucrose and Betaine in Streams Surrounding the Molasses Desugaring by Chromatographic Process (MDC) Carol L. Wambolt*, Doris C. Fleming and Larson H. Caldwell Amalgamated Research LLC The Amalgamated Sugar Company LLC Presented at the ASSBT 40thBiennial Meeting February 27, 2019 Anaheim, CA

Molasses Molasses is defined as the mother liquor (runoff syrup) from the final stages of crystallization. Is produced at about 5% on beet Has a high concentration (about 80%) Has a high amount of sucrose (about 50%) Has about 15% of sucrose coming with the beets Has about 80% of sucrose loss of the beet-sugar factory Has as its most valuable components sucrose, betaine and amino acids Can be desugared by the MDC process to recover sucrose, betaine and minerals

Coupled Loop Molasses Separator Loop 1 Upgrade fraction Material moving ahead in profile Contains sucrose, salts, color and some organic compounds Betaine fraction Slower moving compounds Contains betaine and amino acids

Coupled Loop Molasses Separator Loop 2 (Upgrade fraction from Loop 1 is Feed to Loop 2) Raffinate fraction Leading fraction Contains salts, more highly ionized organic compounds, color Extract fraction Slower moving fraction Contains sucrose and some organics not removed in betaine fraction

Separator streams selected for NIR Model Development Measurement Range of NIR Predictive Models (%w/w) Separator stream Constituent Virgin Molasses Separator Feed Molasses Sucrose 0.2 67 Dilute Betaine Concentrated Betaine Betaine 0.4 50 RDS 0.8 - 89 Amino Acid cut Upgrade Molasses Dilute Raffinate Concentrated Raffinate Dilute Extract Concentrated Extract 5

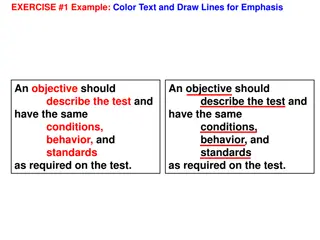

How Do I Build an NIR Prediction Model? 1. Identify measurement goals and select samples which cover the range you expect to encounter in routine use. 2. Mix thoroughly and scan each sample with NIR spectrometer, using appropriate settings, under the same conditions. 3. Analyze all samples using the Primary method (ie. GC, HPLC, IC, etc.) 4. Sample Number: - Studies are routinely published with 20 to 50 samples total for developing an NIR Prediction Model - Based on our experience, 100 samples minimum before model can be used with any level of confidence - Can only predict within the diversity of samples that you have

How Do I Build an NIR Prediction Model? 5. Correlate Primary method measurements with each NIR spectrum. SPECTRAL INSPECTION ALONE IS NOT ENOUGH. A Chemometric software package must be employed to extract chemical and physical information from the complex data. 6. Run a statistical analysis and address spectral variability. A. Examine Derivatives (typically 1st or 2nd ), not raw spectrum (usually) B. Standard Normal Variate (SNV) and Detrending C. PLS or MPLS regression, PCA or other calibration techniques

How Do I Build an NIR Prediction Model? 7. Include validation samples, that are not used to develop the prediction model, to determine the fit and usefulness of the model.

SUCROSE (Dilute Betaine Stream)_NIR v. GC Validation Samples Independent from Model (SUCROSE)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 130 0.45 0.903 0.12 0 30 0.57 0.09

SUCROSE (Dilute Upgrade Molasses)_NIR v. GC Validation Samples Independent from Model (SUCROSE)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 131 21.33 0.988 0.23 0.008 30 22.18 0.19

SUCROSE (Concentrated Extract)_NIR v. GC Validation Samples Independent from Model (SUCROSE)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 136 60.20 0.967 0.45 -0.007 30 61.02 0.38

BETAINE (Reject)_NIR v. HPLC Validation Samples Independent from Model (BETAINE)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 183 0.65 0.999 0.02 0 30 0.57 0.02

BETAINE (Upgrade Betaine Dilute)_NIR v. HPLC Validation Samples Independent from Model (BETAINE)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 172 17.43 0.997 0.24 -0.002 30 18.11 0.23

BETAINE (Upgrade Conc. Betaine)_NIR v. HPLC Validation Samples Independent from Model (BETAINE)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 176 49.60 0.988 0.48 -0.002 30 50.26 0.34

RDS (Dilute Raffinate)_NIR v. Refractometer Validation Samples Independent from Model (RDS)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 342 4.29 0.990 0.11 -0.001 30 4.07 0.09

RDS (Upgrade Molasses)_NIR v. Refractometer Validation Samples Independent from Model (RDS)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 138 28.02 0.982 0.11 0 30 29.22 0.08

RDS (Virgin Molasses)_NIR v. Refractometer Validation Samples Independent from Model (RDS)_NIR Model Quality Parameters N Mean RSQ SEC Bias N Mean SEP 128 81.34 0.992 0.30 0.001 30 81.75 0.25

NIR Advantages - High continuous sampling rate enables automatic process control. - Excellent precision and very good accuracy. - No sample preparation. - Can measure liquid or solid samples. - Can measure multiple sample constituents at once. - Can be made insensitive to product temperature. - Very simple to install, maintain and operate once models have been established.

NIR Advantages - NIR Models can be transferable. Refract. RDS NIR RDS Sucrose w/w HPLC Sucrose w/w NIR Sample 1.47 -3.00 #10 Thick J 66.40 64.93 61.70 64.70 1.64 -4.02 #44 Thick J 67.55 65.91 61.40 65.42 Customer samples blended with an ARi established model Refract. RDS NIR RDS Sucrose w/w HPLC Sucrose w/w NIR Sample 0.35 0.14 #10 Thick J 66.40 66.05 61.70 61.56 0.25 -0.48 #44 Thick J 67.55 67.30 61.40 61.88 (SUCROSE)_NIR Model Quality Parameters Quality Model for Customer use N Mean RSQ SEC Bias 162 60.48 0.972 0.36 -0.003

NIR Limitations - Not a primary method. *Depends on accuracy of the reference method (ie. GC, HPLC, IC, etc.) - Calibration models require careful experimental design. - Initial implementation requires a significant investment in Human Resources. - Lifecycle management: NIRS Calibration models must be revalidated on a regular basis and appropriate change control implemented when necessary. - NIR is not a trace-method, but excellent for bulk measurements. *NIR can measure organic constituents above 0.1% ( Rule of Thumb ).