GaAs - Growth, Applications, and Research Insights

Learn about Gallium Arsenide (GaAs), its growth processes, applications in high-speed circuits, LEDs, lasers, and solar cells. Explore key research areas including solar cell development, crack formation control, and power sensor fabrication on GaAs substrate.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

GALLIUM ARSENIDE NUR NAJIHA BINTI ABD HAMID 1140595

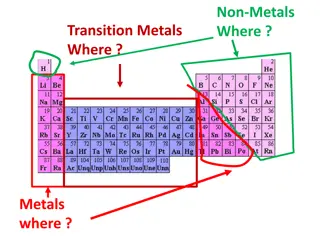

INTRODUCTION Process used to prepare GaAs: - Vertical gradient freeze (VGF) - Liquid encapsulated czochralski (LEC) GROWTH - Bridgman-Stockbarger technique Specialty: Useful in high-speed circuit Direct band gap allows to emit light with high efficiency Not sensitive to heat because of their wide band gap Less noise at high operating frequencies

Mostly used - monolithic microwave integrated circuits - LEDs - Laser - Solar cells

INTRODUCTION OF REFERENCES Journal 1 - reviews about the current status of the development of solar cell from various types of materials - made up of from different materials Journal 2 - ZnO nanoparticle is spray-coated on the top of the GaAs solar cell - critical loss in solar cell caused by large refractive index mismatch between GaAs and air - ZnO is from porous film can provide an effective refractive index Journal 3 - proposed new method in controlling the crack formation using the notch patterns - open circuit voltage and the efficiency of photovoltaics cells were improved

Journal 4 - capacitive power sensors have been fabricated on GaAs substrate - limitations in sensitivity of the capacitive power sensor - proposed a differential power sensor based on seesaw-type MEMS membrane Journal 5 - fabrication of the thermoelectric microwave power sensors - to design the isolation structure to optimize the efficiency Journal 6 - reviews about the OP GaAs crystals - presence of defects can contribute to the optical losses - studied a spectroscopic cathodoluminescence

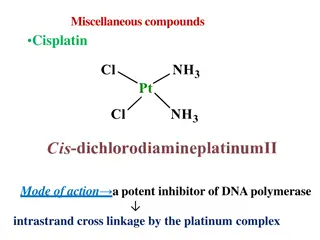

COMPARISONS OF THE JOURNALS Materials Composition Method/ Process Characterization Properties p-junction - Band gap=1.43eV close to theoretical (1.34eV) Good in electronic properties Journal 1 Alloying GaAs with other III-IV elements such as InGaP Epitaxial lift-off technique to produce excellent single crystal GaAs -GaAs (200nm) -InGaP (500nm) n-junction - High spectral absorbance -GaAs (200nm) a) low density coating, 35% coverage Scanning electron microscope (SEM) Enhancement of the solar cell external quantum efficiency (EQE) Journal 2 Coated with ZnO nanoparticle Solution-based process b) medium density coating, 75% coverage -16% short circuit current -10% increase in PV efficiency c) high density coating, 100% coverage

Materials Composition Method/ Process Characterization Properties For GaAs: -Nanoscale patterning method TEM images - Show the average threading dislocation density (TDD) measurements Efficiency Journal 3 Fabricated GaAs on silicon substrate Base layer 2.9 micrometers - Deep reactive-ion etching (DRIE) process Emitter layer 100 micrometers Collector layer 50 nanometers GaAs 400 micrometers GaAs substrate - Monolithic microwave integrated circuit (MMIC) process High sensitivity due to change in capacitance Electric property Journal 4 - Combination of various elements to form a substrate - Show differential in capacitance Electrodes 0.45 micrometers Silicon nitride 0.23 micrometers as insulator layer - Microelectrome chanical systems (MEMS) technology based on seesaw type Polyimide 1.6 micrometers

Materials Composition Method/ Process - MMIC process Characterization Properties GaAs 500 micrometers Scanning electron microscope (SEM) Thermal conduction property Journal 5 Membrane structure is defined with the bulk micromachining technology on GaAs -MEMS technology based on thin membrane structure Orientation- patterned GaAs (OP GaAs) crystals GaAs (001)/Ge/GaAs (001) - Fabricated using molecular- beam epitaxy (MBE) Field emission scanning electron microscope (FESEM) Optical properties Journal 6 - measured cathodoluminescence (CL) study - Hydride vapor-phase epitaxy (HVPE) technique Spectrum imaging (SI) -various spectral parameter such as intensity, peak of wavelength etc.

INVENTION 2009, Samsung Guru E1107 is introduced Small solar cell could not provide a lot of power and the phone had to absorb an hour's worth of solar energy GaAs has great ability to emit light Solar cell implanted on the back side of the smartphones Solar cell tends to be dark Help people when doing outdoor activities